We can’t calculate each and everything in the field.

Sometimes we have to act quickly to move on. Every professional have maintained their own set of thumb rules.

What is Thumb Rule?

At first, we have to understand the meaning of the thumb rule before jumping into the discussion.

- Thumb rules are “ Approximate Value”.

- Thumb Rules has no unit systems

We use the thumb rules for almost every calculation like concrete calculation, manpower estimation, the material requirement for plastering, wastage’s calculation, brickwork calculation, etc.,

For example,

What is the requirement of bricks for 1 Cubic metre? As per the calculation 625 nos.

But we Say Approx 600 nos. It is called a thumb rule. Because we can not estimate every time according to the individual requirement.

Thumb rule for Manpower Productivity Estimation

Manpower productivity thumb rules will be useful to calculate the total manpower required for your next schedule.

| SI | Manpower | Activity | Output – 8 Hours |

| 1 | Mason – 1 Male mazdoor – 0.75 Female Mazdoor – 0.5 |

Brick Work | 45 Cft |

| 2 | Mason – 1 Male mazdoor – 1 Female Mazdoor – 0.5 |

Wall plastering | 120 Sft |

| 3 | Mason – 1 Male mazdoor – 0.75 Female Mazdoor – 0.5 |

Ceiling Plastering | 90 Sft |

| 4 | Carpenter-2.25 Foreman- 0.2 Helper- 2.25 |

Shuttering Work | 11 Sqm |

| 5 | Bar Bender – 1 Nos Helper – 1 Nos |

Steel Work | 100 Kg |

| 6 | Tile Mason – 1 Nos Helper – 1 Nos |

Tile Work | 10 Sqm |

| 7 | Mason – 2 Male mazdoor – 1.75 Female Mazdoor – 1.75 |

Block Work | 2 m3 |

| 8 | Male Coolie – 5 Nos Female Coolie – 4 Nos |

Earth Digging | 1000 Cft |

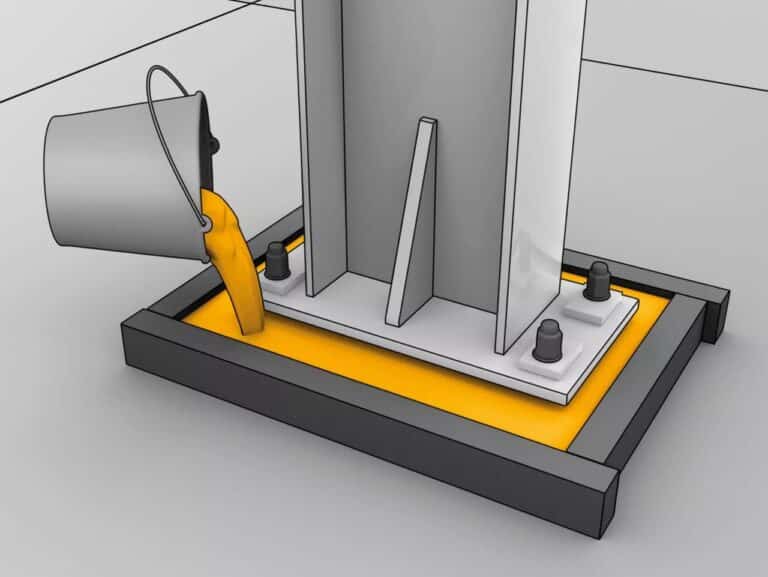

Thumb rule for concrete work

The concrete ingredients will be vary based on the mix ratio.

For Example,

If the Plinth area is 100 Sq.ft (10 x 10) and the required concrete volume is 100 x 0.04 = 4 m3 with M5 mix ratio means

Now from the below table which is for 1 m3

Required Concrete ingredients for 4 m3 of M5 is

Cement – 2.77 x 4 = 11.08 bags

Sand – 0.48 x 4 = 1.92 m3

Coarse aggregate = 0.96 x 4 = 3.84 m3

Thumb Rule of Concrete material requirement

| Grade | Ratio | Cement in Bags | Sand in m3 | Coarse Aggregates in m3 |

| M5 | 01:05:10 | 2.77 | 0.48 | 0.96 |

| M7.5 | 01:04:08 | 3.41 | 0.47 | 0.95 |

| M10 | 01:03:06 | 4.44 | 0.46 | 0.92 |

| M15 | 01:02:04 | 6.34 | 0.44 | 0.88 |

| M20 | 01:05.5 | 8.06 | 0.42 | 0.84 |

| M25 | 01:01:02 | 11.09 | 0.39 | 0.77 |

Must Read:- What is water cement Ratio

Thumb rule for Plastering Work

For plastering, the material quantity will vary based on the different mix ratios like concrete and the thumb rule for plastering work has listed below.

| Type of Plastering | Mix ratio | Thickness in mm | Cement Bags/Sqm | Sand m3/Sqm |

| Inner Plastering | 1:3 | 15 | 0.16 | 0.017 |

| External Plastering | 1:4 | 20 | 0.17 | 0.024 |

| Rough Plastering | 1:5 | 16 | 0.11 | 0.020 |

| Ceiling Plastering | 1:2 | 12 | 0.17 | 0.012 |

To know more How to calculate material for Plastering work

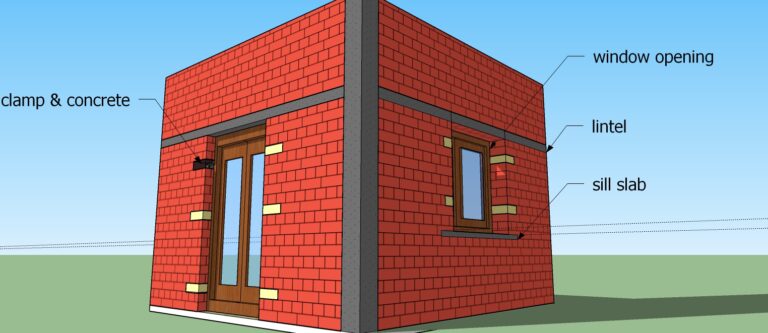

Thumb rule for Brick Work

The size of brick 190mm x 90mm x 90mm

Number of bricks per cubic metre (m3) = 500 Nos

Must read: How to calculate the number of bricks

| Mix Ratio and brickwork thickness | Mortar Thickness in mm | Cement in Bags | Sand in m3 |

| 1:6 200mm Thk | 10 | 1.4 / m3 | 0.30 |

| 1:5 200mm Thk | 10 | 1.7 / m3 | 0.25 |

| 1:4 100mm Thk | 10 | 0.15 / m2 | 0.035 |

| 1:5 200mm Thk Block | 10 | 0.15 / m3 | 0.02 |

Thumb rule for Steel in RCC

The steel cost very expensive compared to other construction material and the excess purchase of steel requirement impact the project budget. A good designer restrains steel utilization.

| Type of Structure | Steel Kg/Sft |

| Residential Building | 2.5 to 4.5 |

| Commercial Building | 4.5 to 5.5 |

| Mass Project Tall or heavy Structure | 6 to 8 |

The steel percentage against concrete volume will vary based on the structural element and the minimum and maximum percentage of steel utilization have listed below as per IS standard.

The Thumb rule for steel in RCC has listed below.

| Structural Element | Percentage of Steel in Concrete |

| Slab | 1% |

| Beam | 1% to 2% |

| Column | 2.50% |

Must Read: How to calculate steel weight for Reinforcement

Example calculation:

Steel quantity = Volume of Concrete x Density of Steel x % of Steel.

For example, if a volume of concrete 1 m3 for a slab.

Approx Steel requirement = 1 x 7850 x 1% = 78.5 Kg/m3.

Read: Bar bending Shape codes

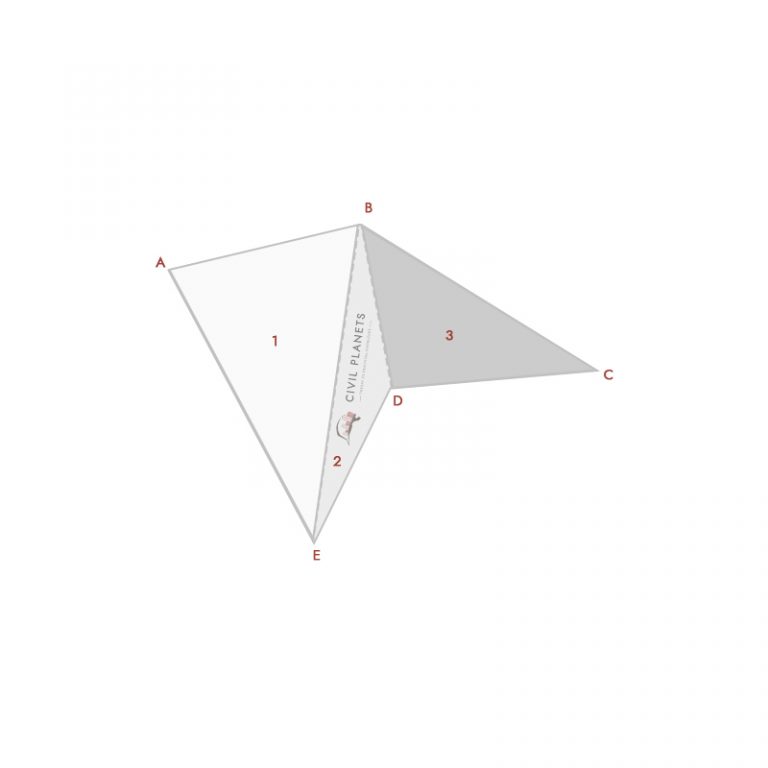

Thumb rule for shuttering work

The shuttering work is called by another name “Form Work” because it gives a uniform shape and smoothness for the concrete. Generally, it takes 10% to 15% of the cost of the total budget.

The Thumb rule for shuttering work is listed below.

| Type of Concrete Element | No of Times Sqm Per cubic metre |

| Foundation | 2 to 3 times of concrete volume |

| Column | 11 to 13 times of concrete volume |

| Beam | 11 to 12 times of concrete volume |

| Slab | 6 to 8 times of concrete volume |

For example, if the slab concrete volume 1 m3 then the approx shuttering requirement is 1 x 6 = 6 Sqm.

If we have missed anything please do let us know to update!

Do you have any kind of thumb rules for yourself? If so share it with us in the comment section we would like to also learn something from you.

9 Comments

i want to knowhow to calculate the plaster work of a round shape area..

Hello, Alderson this article “plastering calculation” will help you know the calculation of plastering.

Same method explain just you have to calculate the area of the round shape portion. Then find the volume as explained.

There is a typo error in M7.5 grade sand quantity. one thing is to all information are use full.

Thank you. We have updated the error.

For the thumb rule any IS CODE like IS1200 for measurement.

Siva, no IS code for thumb rule

How to calculate the quantity of size stone , boulders , solid blocks , Cement , msand , steel

For 1 m3 work

Storm Water Network, Combined Wastewater Network, Electrical Networks (MV network), Electrical Networks (LV, Streetlighting and UPS), PSS System Network – (Design, procurement, construction, installation, testing and commission of the Storm Water Infrastructure)

per square meter cost