The compressive strength test of concrete is one of the destructive tests widely done at the site to find out the compression strength of a particular concrete batch.

What is the Compressive Strength of Concrete?

The ability of hardened concrete cube to resist the compression loads applied on the surface is known as

Otherwise, the compressive strength of concrete is defined as the maximum crushing stress endured by the concrete.

Purpose of this Test

Assume a slab at our site is designed to cast M25 grade of concrete, but we could not define its strength in the semi-solid state.

For that matter, A certain quantity of concrete shall be cast as a cube while concrete pouring time to find the compressive strength of that concrete batch. The cube will be preserved and curated well for almost 28 days to be tested by the Compression Testing Machine.

Compressive Strength of Concrete Test

Apparatus Required

- Steel Mould (150mm x 150mm x 150mm)

- Tamping rod

- CTM Machine

- Trowel

- Weighing machine

Procedure

Cube Casting

|

|

|

- Estimate the adequate ingredients to prepare the concrete with a proper water-cement ratio.

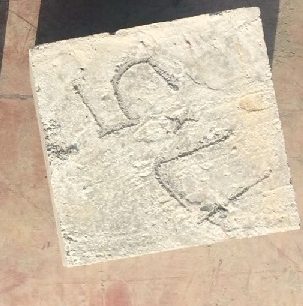

- Ensure that the cube mould should be free from dust and rust.

- Now, pour the concrete into the mould by proper compaction with the help of a tamping rod.

- Finish the top surface as smooth by the trowel.

- The mould should be covered with a gunny bag and placed undisturbed for 24 hours at a temperature of 27 ° Celsius ± 2.

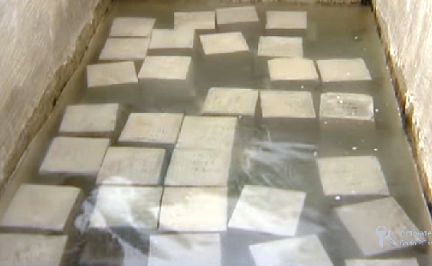

- After 24 hours, the cube specimen shall be removed from the mould, and it should be immersed into the water for 7 or 28 days based on the test.

Method of Testing

|

|

|

- The cube should be removed from the water 30 minutes before the test, and it should be in dry condition.

- The specimen should be weighed before the test.

- The specimen should be placed between the plate with proper alignment.

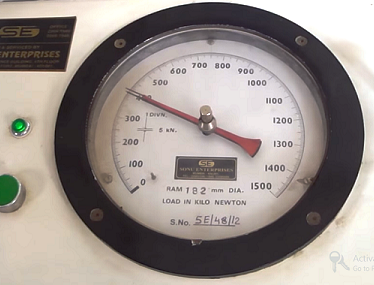

- Now, apply the load (kilonewton) gradually to the specimen.

- The specimen will break at maximum load (1 Division = 5 KN), which is noted down as the crushing value of the cube.

- The average (Minimum Three Sample) crushing value should be note down as the compression value of the selected concrete batch.

Video Courtesy – NCTEL

How To Calculate Compressive Strength Of Concrete Value? – Formula

Compressive Strength of concrete cube = Maximum load/Area of the cube

Example Calculation

- Assume that the compression load is 375 KN (1 Kg = 9.81 N)

- Cross Sectional Area – 15 x 15 = 225 Sqcm.

- Compressive Strength = (375 x 1000/225) = 1666/9.81 = 169.82 Kg/Sqcm.

Lab Report

| Grade | Age of Test | Specimen | Load (KN) | Tensile Strength (Kg/Sq.cm) | Average Strength |

| M10 | 28 Days | Sample 1 | 300 | 136 | 138 |

| 28 Days | Sample 2 | 290 | 131 | ||

| 28 Days | Sample 3 | 325 | 147 |

Frequently Asked Doubts

-

Why is the cube test done at 7 days, 14 days, and 28 days?

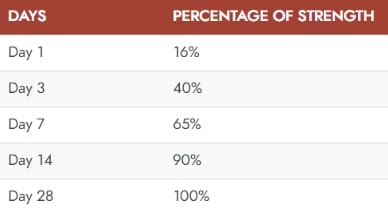

Simple. The concrete takes 24 hours to attain 16% of its strength, and the strength will increase gradually.

The concrete attains its full strength in 28 days. Experts already recorded the concrete strength change at specific time intervals like below.Gradual Difference of Compressive Strength of Concrete

So it is easy for us to compare the strength with that reference value at a specific time interval. -

Why was the size of mould chosen 150mm x 150mm x 150mm?

There is no such thing that we only have to use 150mm moulds.

We can also mould any square cubes. But it requires a higher capacity CTM machine to calculate the values such as 300 tonnes, which does not cost-friendly. So we stick to the 150mm mould.

Also, it is easy for us to carry or transfer the cubes inside the site/field.

-

What is the Purpose of Cube Weighing?

To identify the unit weight of concrete. You may know that the unit weight of concrete is 2400 kg/m3.

How could it be measured?

Simple. Assume, the approx weight of one concrete cube = 8 kg

Then the volume of concrete = 0.15 x 0.15 x 0.15 = 0.0033 m3; So for 1 m3 = 8/0.0033 = 2400 kg/ m3. Since the concrete weight itself has also been assumed for the structural calculations, if it exceeds the assumed value, then the load on the structure will likely increase. -

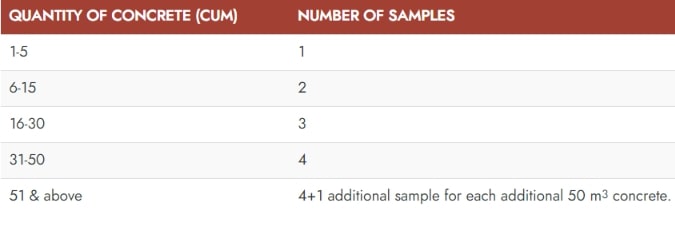

How many samples should be taken for the test?

As per IS Code, the sample selection for the concrete cube test has listed below.

-

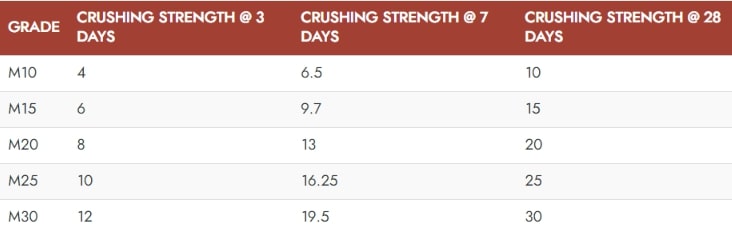

The minimum value of Compressive Strength for a cube

As per IS 456, the individual compressive value of a concrete cube should not be less than 75% of its grade.

Example – If the concrete grade is M20, then the individual crushing value should not be less than 15 N/Sqmm. The individual crushing value difference between the cube should not be greater than 15%.

Hope you enjoyed the topic. Happy Learning 🙂

4 Comments

Why should the concrete specimens be immersed in water before testing?

For curing purposes

from what time the days are calculated for testing like 7 days 28 days…is it from the time of casting or after 24hrs of casting like removal of cubes from moulds and putting in curing tank

Is very educative