Estimation of any material looks daunting until unless you learn the nitty, gritty of the calculation.

In this post, We are going to discuss the concrete material calculation with an example.

- For Slab calculation ( 5m x 2m x 0.1m)

- For Beam calculation ( 5m x 2m x 0.3m)

- For Circular Column ( 6m height & 0.3 m diameter)

How to calculate concrete volume?

Example Concrete Volume Calculation

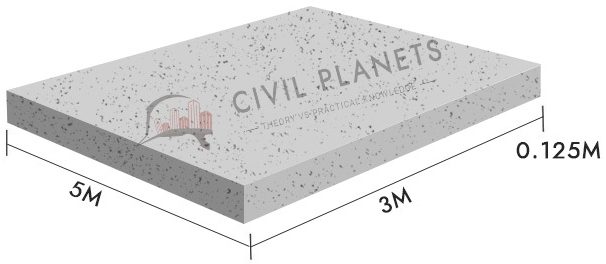

For Slab,

Length – 5 Metre | Breadth – 2 Metre | Width – 0.1 Metre

Make sure all the measurements are in the same unit

Volume = Length x Breadth x Width = 5 x 2 x 0.1 = 1 m3

So the required concrete volume = 1 m3

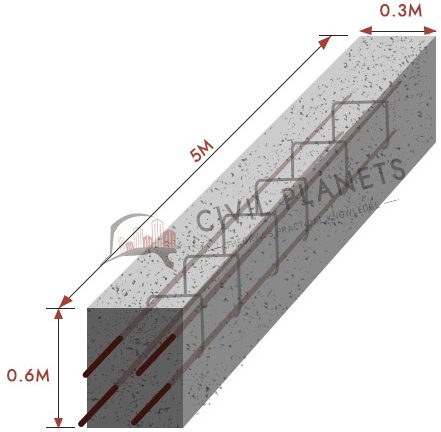

For Beam,

Length – 5 Metre | Breadth – 2 Metre | Width – 0.3 Metre

Make sure all the measurements are in the same unit

Volume = Length x Breadth x Width = 5 x 2 x 0.3 = 3 m3

So the required concrete volume = 3 m3

For Circular Column,

Height – 6 metres, Diameter – 0.3 metre

Make sure all the measurements are in the same unit

Formula for Circular Volume = π r2 h = 3.14 x (0.15)2 x 6 = 0.42 m3

So the required concrete volume = 0.42 m3

Now we have calculated the required volume. It’s time to calculate the micro-ingredients.

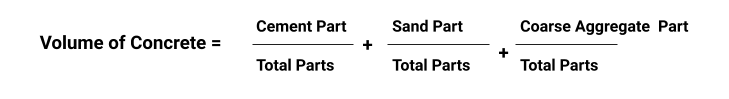

Concrete Material Calculation

For the above slab volume ( 5m x 2m x 0.1m) = 1 m3

We need 1 m3 of wet volume concrete of M20 Mix, (Mix Ratio, M20 = 1: 1.5 : 3)

So Total Parts = 1+1.5+3 = 5.5 Parts which gives Dry volume that means before adding water content.

We have discussed the effect of water on concrete.

Adding Void Ratio Compressibility

So to get 1 m3 of wet concrete, we have to multiply the dry volume by 1.55.

What is 1.54 constant in concrete calculation?

Bulking of Sand – If the moisture is present in the sand, then it makes the sand look bulkier, which could result in inadequate sand proportion in the concrete ratio.

If we need to add 1m3 sand in the concrete mix ratio, we take 1.3 m3 (30% more). The reason for that is the moisture content present in the sand makes it a little bulkier. The 5% to 8% of surface moisture will increase the bulking of sand up to 20% to 30%. When we add more water (more than 8%) to the sand, the thin film will disappear, and volume decreases.

Void Ratio – If you fill the shuttering area with blue metal alone it has lots of voids in it which also need to be filled by the other materials such as sand & cement. Such void gap is known as void ratio compressibility which is 20% for coarse aggregate.

So if we need 1 m3 of concrete in wet condition we have to take consideration of the bulking of sand and void ratio compressibility for both coarse & fine aggregate (35%+20%) = 55%

Thus every time you need to calculate the volume of concrete you need to add the above percentage with dry volume

Wet Volume of concrete = Dry Volume of concrete + 55% of dry volume of concrete or

Wet Volume of concrete = Dry Volume of concrete x 1.55

So whatever volume we get from the above formula, we need to multiply the value with 1.55%

Now back to the calculation,

Sum of total parts = 1+1.5+3 = 5.5 Parts

Volume of concrete = (1 Cement Part)/5.5 + (2 Sand Part)/5.5 + (4 Coarse Aggregate Part)/5.5)

Therefore Volume of Cement = 1/5.5 x 1.55 (Bulkage & Wastage)

Volume of Sand =1.5/5.5 x 1.55

Volume of Coarse Aggregate = 3/5.5 x 1.55

So the required

Cement Volume – 0.282 m3 or 8.14 Bags

Sand Volume – 0.423 m3

Coarse Aggregate – 0.845 m3

Water Cement Ratio Calculation

From the IS Code standard, Assuming the water-cement ratio for M20 is 0.55.

Therefore required water quantity = Cement Volume X WC Ratio = 0.282 X 0.55 = 0.1551 m3

Unit weight of water = 1000 Litres / m3

Water Quantity in Litres = 155.1 Litres

The material requirement for Different Grade of Concrete

| Grade | Ratio | Cement in Bags | Sand in m3 | Coarse Aggregates in m3 |

| M5 | 1 : 5 : 10 | 2.77 | 0.48 | 0.96 |

| M7.5 | 1 : 4 : 8 | 3.41 | 0.047 | 0.95 |

| M10 | 1 : 3 : 6 | 4.44 | 0.46 | 0.92 |

| M15 | 1 : 2 : 4 | 6.34 | 0.44 | 0.88 |

| M20 | 1 : 1.5 : 3 | 8.06 | 0.42 | 0.84 |

| M25 | 1 : 1 : 2 | 11.09 | 0.39 | 0.77 |

9 Comments

M30 concrete using only 380kgs with admixture is it possible

Yes you can!.

The mix proportion of M30 (Design Mix) is based on the weight of the material. As per the design some percentage of admixture might be mixed with the concrete.

Sir, do u have a conatruction materials calculator software in google playstore, then if u have it software pls give a link of software. Thank u

We are working on that!.. update will soon

Sir, i cant understand the difference between ACI code and IS code of water cement ratio. Pls explain me

Sir, i cant understand the difference between ACI code and IS code of water cement ratio. Pls explain me

Sir,

can i know your insta ID?

How do you get 8 bags of cements , what about sand and gravel in load. I want details explanation of the calculation