As a civil engineer, you should need to ensure that you are using good quality materials for the construction. Since poor quality material indirectly affects many factors including project budget

Importance of Brickwork Quality Check

For Instance, take brickwork

If the bricks purchased are not up to the mark then the following consequences occur

- Construction budget increases

- Affects the structure strength

- Leads to manpower wastage (due to rework)

- Less labour output

So In this post, we are going to discuss factors that affect the quality of brick and how to choose the right quality?

Factors that Indicate the Brick Quality

- Uniformity

- Soundness

- Hardness

- Water Absorption

- Efflorescence

- Durability

Uniformity in Size, Shape & Colour

- A good brick should have uniform shape & size. It might be a rectangular shape without any dropsy on its body.

- The bricks surface should not be smooth otherwise the mortar will not paste the brick.

- The brick should contain uniform colour and free from cracks.

- It should have a copper colour & might be bright.

As per IS specification the size of the brick should be 190mm x 90mm x 90mm and should weigh approx 3 Kg.

Reason to Check – Uneven surface & size will make the labour to work more to shape the brick before placing which affects the labour output per day

Soundness

- A good brick should give a clear metallic ringing sound when struck with another brick.

Hardness & Strength

- A good brick should be hard, even fingernails cannot able to make an impression on its surface.

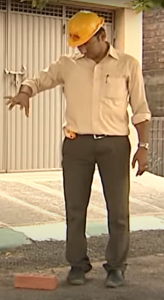

- It should not break when it’s fallen from the 1.2 – 1.5metre height on the ground or struck with another brick.

- The crushing strength of bricks should not be less than 3.5 N/Sqmm. If the brick is high quality then it should have a crushing value minimum of 14 N/Sqmm.

Reason to check – At the site, labours often shift the materials from one floor to another also sometimes slips accidentally from hands while working. If the brick can’t tolerate that fall then there will be a lot of brick wastage occurs

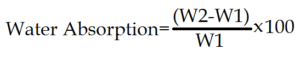

Water Absorption

The brick should not absorb more than 20% of its dry weight of water when the brick immersed in water for 24 hours.

- Weigh the dry weight of brick (W1).

- Immerse the brick in water for 24 hours then weight it (W2).

Now the Percentage of water absorption,

Reason to Check – The cement mortar has specified amount of water-cement ratio to increase the bond strength between the bricks. If the brick absorbs more water the mortar starts to dry and leads to weak brick bonding.

Efflorescence

If there are lot white smudge on the brick then the brick contains much alkaline salt. It causes the efflorescence on its surface & disintegrated the bricks.

How to do the Efflorescence Test?

Actually, it is very simple

- Immerse a brick in water for 24 hours.

- After 24 hours take out the brick, if the white deposits cover the brick more than 20% of its surface then avoid the brick.

Reason to Check – Efflorenscence means the bricks contain more harmful salts which dissolves in mortar water and collapse the brick structure.

Frog Impression on brick

The brick should have frog impression which increases the bond strength with mortar.

Durability

A good brick should resist the effects of temperature, rain, frost action & fire up to 1200° C. Don’t forget the quality of bricks will increase the life of the wall.

Video

Video Courtesy – UltraTech Cement

2 Comments

very good sir

You are Welcome!.