In the field, we will conduct tests for almost all materials. Those tests are not accurate and don’t have any high accuracy. The slump test is not an exception.

What is meant by the slump cone test?

A slump test is being done at the site to find out the workability and consistency of the fresh concrete. It does not give accurate results but it is useful to detect the uniformity of concrete mix.

Since its main apparatus is a conical shape mold it is called a Slump Cone Test.

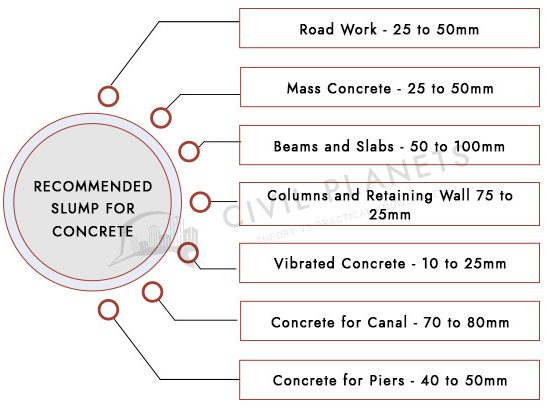

Ideal Value of Slump for works (Chart)

Uses of Slump Test

As mentioned above to find out the workability of fresh concrete.

Most of the concrete defects such as shrinkage, crazing are directly related to the water-cement ratio. Using the slump test, it is possible to identify the required slump for the specific work and can avoid unnecessary defects without waiting for the detailed lab tests such as

Slump Test – IS code

The concrete slump test will be conducted at the site as per IS 1199. Let’s start with the test procedure.

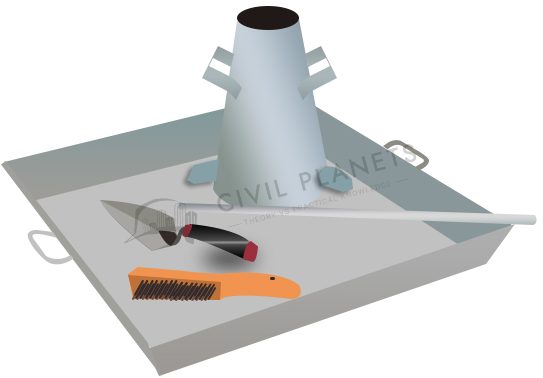

Apparatus Required

- Trowel

- Tamping Rod – 60 Cm length

- Measurement Scale

- Smooth Surface Pan

- Slump Cone

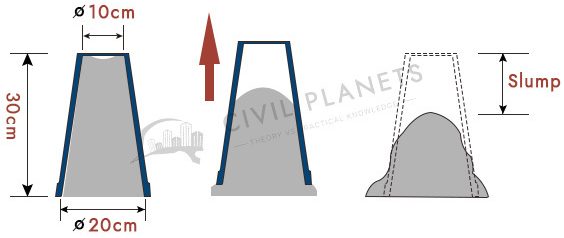

Slump Cone Dimensions

- Height – 30 Cm

- Top Diameter – 10 Cm

- Bottom Diameter – 20 Cm

- Dia of the Tamping rod – 16mm

Test Procedure

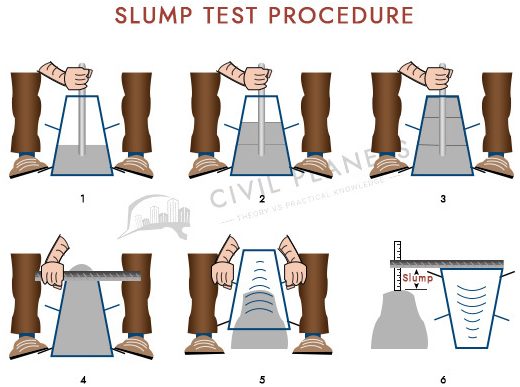

All the apparatus should be free from moisture or any other affluent and also it should be in dry condition.

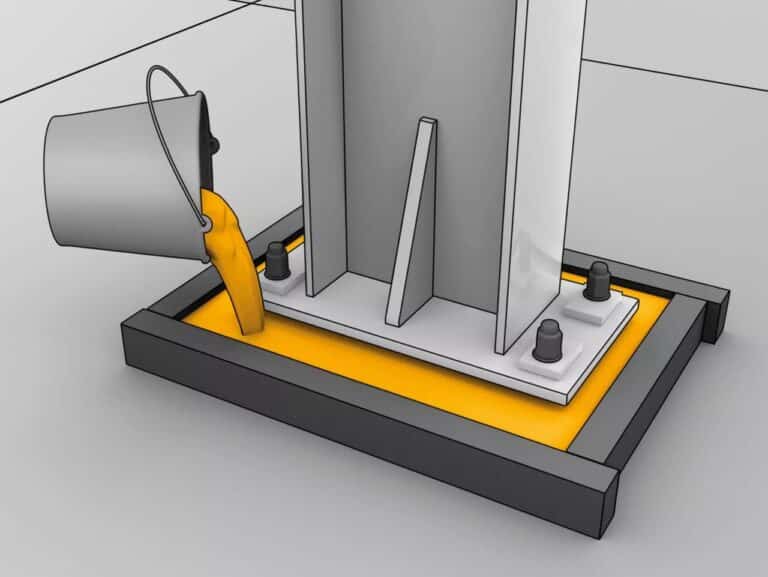

- Step 1 – First, place the slump cone mould over the smooth surface pan then fill the fresh concrete in layers up to the slump cone mould top.

- Step 2 – Each layer of filled concrete should be tamping up to 25 times by the tamping rod.

- Step 3 – Fill concrete up to the top of the cone.

- Step 4 – Level and remove the excess concrete from the top.

- Step 5 – Slowly remove the cone mould in the vertical direction and now the concrete will fall down on the pan.

- Step 6 – Now measure the difference between the height of the slump cone mould to the concrete subsidence. The slump value will be measured in millimetre.

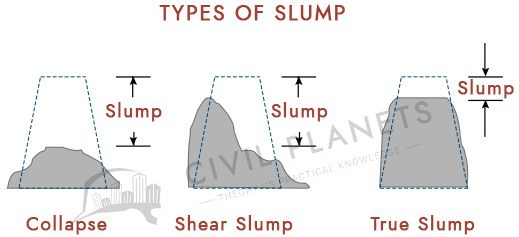

Types of Slump

Concrete slump results can be classified into 3 types such as

- True Slump – When the slump cone mould removal, the concrete eventually slides down but it possesses the mould shape.

- Shear Slump – When the slump cone mould is removed, the half portion of the concrete slides down on the pan is called Shear slump and will do the retest.

- Collapsed Slump – When the slump cone mould is removed, the concrete falls fully on the pan. It is called Collapsed slump and it is not suitable for pouring.

What is a zero slump concrete?

When the concrete not falling down on the pan after removing the mould is called zero slump. It states that the concrete was too stiff and had less water-cement ratio.

Happy Learning 🙂

1 Comment

Amazing thank you