The cement reacts with water and turns into a paste to form a layer on other ingredients to make the (concrete) bond stronger.

The optimum quantity of water and cement produces a strong, homogeneous mix material that gives consistency to the concrete or mortar.

What is the consistency test of cement?

The consistency of cement is the minimum water requirement to start the chemical reaction between water and cement.

This test helps to identify the minimum water required to make the cement paste.

Why do we do cement consistency tests?

The cement starts hydrating when it reacts with the water and hardens itself.

Higher water quantity will give high workability of concrete, but at the same time, it will lead to bleeding, segregation, which will affect the concrete strength.

Lower quantity of water decreases the workability, and it does not make a homogeneous concrete element or mortar. So to make a proper water-cement ratio that gives excellent workability, strength, and durability of concrete, we have to conduct this experiment.

The minimum quantity of water required to make uniform cement paste can be determined by the cement test’s standard consistency. This test also helps identify the initial and final setting time of cement and soundness of cement test.

| Name of the experiment | Amount of water required |

| Soundness (Le-chatelier method) | 0.78 P (P=Consistency of standard cement paste) |

| Setting time | 0.85 P (P=Consistency of standard cement paste) |

Importance of consistency test of cement

The usage of cement in the site will affect by the following factors,

- Fineness of cement

- Weather conditions

- Defects in manufacturing

- Too much silica in cement

So the necessity of the cement test’s consistency is to find the required water to get an excellent and uniform cement paste in concrete or mortar considering the above factors.

Standard Consistency of OPC will be anywhere from 25-35%. That means we need 25-35% of the water in volume (based on cement quantity) to make a standard consistency of cement.

Assuming we have to calculate the water required for a 1000g of cement. It has 25% consistency. Therefore to prepare a standard consistency, we required = 1000 x 25% = 250g amount of water.

Determination of standard consistency of cement

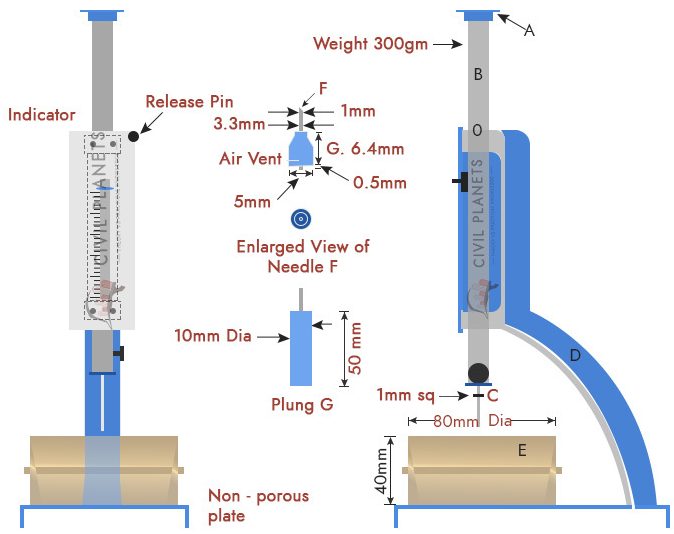

The standard consistency of cement test should be performed as per IS code 4031 part 4 specifications by the Vicat apparatus mentioned in IS code 5513.

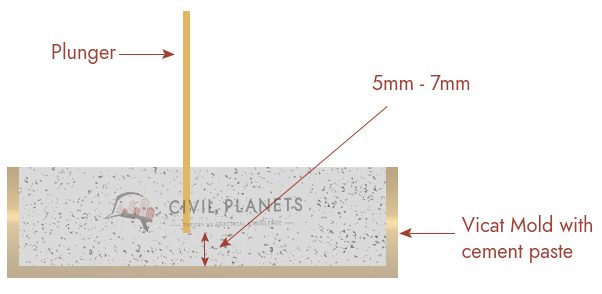

The required water for making cement paste can be found by the plunger of the Vicat apparatus penetrating the cement paste about 5mm to 7mm bottom from the Vicat mould.

Apparatus Required

- Vicat apparatus – Vicat Apparatus consists of a plunger with a needle, which used to penetrate the cement specimen up to the depth of 5mm to 7mm and above.

- Weighing balance – Up to measure 1000g with 1g accuracy

- Stop Watch

- Measuring Cylinder 200 ml

- Glass Plate

- Vicat Mould

- Tray

- Trowel

Test Procedure

- Fix and place the Vicat apparatus on a flat surface and make necessary adjustments.

- Now take 400gm of cement specimen and add 28% of water by the weight of cement and mix gently for up to 3 to 5 minutes.

- Then fill the cement paste into the Vicat mould and remove the excess cement paste by the trowel.

- Now place the Vicat mould on the Vicat apparatus and release the plunger gently by contacting the cement paste surface.

- Then release the plunger and allow it to penetrate the cement paste and note down the reading from the gauge scale from the bottom of the Vicat mould.

- Now again, add water with cement paste at a different water ratio until the reading lies between 5mm and 7mm.

Results

| SI | Quantity of water added (ml) | Depth of penetration (mm) |

| 1 | ||

| 2 | ||

| 3 |

The required water amount has been calculated in percentage,

P = (W/C) x 100

P – Percentage of water

W – Weight water added

C – Weight of cement

Test Precautions

- The test must be performed at room temperature.

- The apparatus should be clean from dust and moisture.

- The plunger should be clean after every penetration.

- The cement should be mixed on a glass sheet.

- Ensure that there is no other vibration near the apparatus.

Happy Learning 🙂