Before diving into the topic, I hope you read the basic topics that we have covered already

- Difference between one way slab and two way slab

- Difference between Main Bars & Distribution Bars

- Why is the Crank rod provided?

- What is development length and lap length?

The above posts help a lot to understand the topic much better.

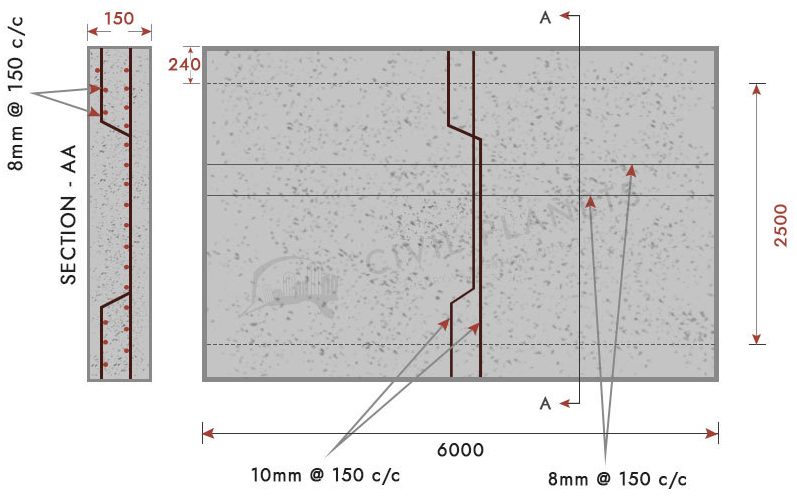

One way Slab Reinforcement Details

- Slab Size = 6000 x 2500 x 150

- 10mm Main Bars @ 150mm c/c spacing

- 8mm Distribution Bars @ 150mm c/c Spacing

- Slab thickness is 150 mm

- Top Extra Bars – 8mm @ 150 c/c

- Beam Cover – 25 mm

Bar Bending Schedule for One Way Slab

Step 1 – Find out the total Number of Main Bars & Distribution Bars

- Number of Main Bars = (Length of Longer Side / Spacing) + 1 = (6000/150)+1 = 41 Numbers

- Number of Distribution Bars = (Length of Shorter Side / Spacing) + 1 = (2500/150)+1 = 18 Numbers

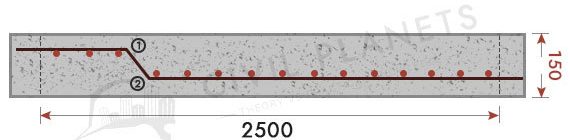

Step 2 – Find Out the Cutting Length of Bars (Main bar & Distribution bar)

- Cutting Length of Bar = Clear Span (Lclear) + (2 x Beam Width) – (2 x Concrete Cover) + (1 x Inclined Length) – (45° bend x 2)

Therefore, Inclined Length D = 0.42 x d

Where, D = Slab thickness – 2 x Clear Cover – Bar Dia = 150-(2*25)-10 = 90 mm

Inclined Length = 0.42 X 90 = 37.8 mm

- Cutting Length of Main Bar = Clear Span (Lclear) + (2 x Beam Width) – (2 x Con. Cover) + (1 x Inclined Length) – (45° bend x 2)

= 2500+(2*240)-(2*25)+37.8-20 = 2947.8 mm = 2.95 m

- Cutting Length of Distribution Bar = Clear Span (Lclear) – (2 x Con. Cover)= 6000 – 50 = 5950 mm or 5.95 m

Step 3 – Find out the number of Top Extra Rods (for L/4 length)

- Number of Top Bars = Crank Length (L/4) / Spacing + 1 = ((2500/4)/150)+1 x 2 side = 10 Numbers

- Cutting Length of Top Bars = Same cutting length as distribution bars (5.95 m)

| Description | Dia of Bar | No of Bars | Cutting Length (m) | Steel weight per metre | Qty (Kg) |

| Main Bar | 10 | 41 | 2.95 | 0.62 | 74.98 Kg |

| Distribution Bars | 8 | 18 | 5.95 | 0.40 | 42.84 Kg |

| Top Extra Bars | 10 | 10 | 5.95 | 0.62 | 36.89 Kg |

| Total |

154.71 Kg | ||||

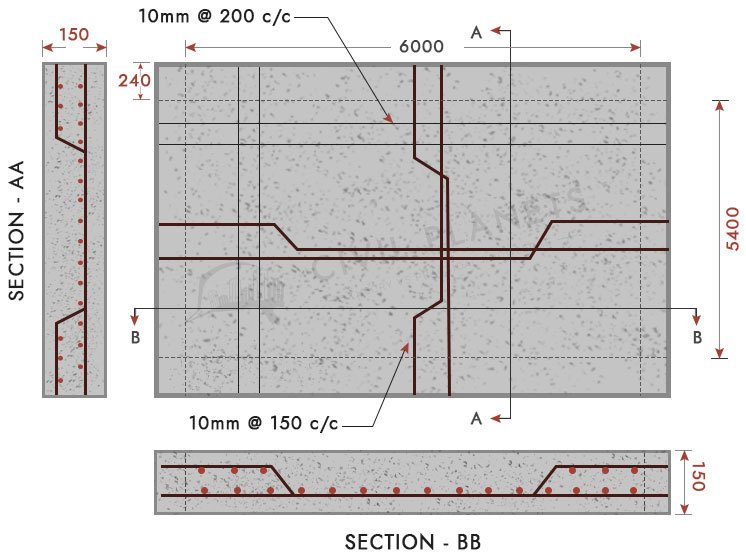

Two Way Slab Reinforcement Details

From Drawing

- Slab size – 6000 x 5400 x 150

- 10mm Main Bars @ 150mm C/C spacing

- 10mm Distribution Bars @ 200mm C/C Spacing

- Development Length Ld = 40d

- Top Extra Bar 8mm @ 150 mm c/c (both direction)

Bar Bending Schedule for Two Way Slab

Step 1 – Find out the Total Number of Main Bars & Distribution Bars

- Number of Main Bars = (Length of Longer Side / Spacing) + 1 = (6000/150)+1 = 41 Numbers

- Number of Distribution Bars = (Length of Shorter Side / Spacing) + 1 = (5400/150)+1 = 28 Numbers

Step 2 – Find Out the Cutting Length of Bars

- Cutting Length of Bar = Clear Span (Lclear) + (2 x Beam Width) – (2 x Con. Cover) + (1 x Inclined Length) – (45° bend x 2)

Therefore, Inclined Length D = 0.42 x d

Where, D = Slab thickness – 2 Side Clear Cover – Bar Dia = 150 – (2*25) – 10 = 90 mm

Inclined Length = 0.42 X 90 = 37.8 mm

- Cutting Length of Main Bar = Clear Span (Lclear) + (2 x Beam Width) – (2 x Con. Cover) + (1 x Inclined Length) – (45° bend x 2)

where 45° bend = 1 d

= 5400 + (2*240) -(2*25) + 37.8 – (10*2) = 5847.8 mm = 5.85 m

- Cutting Length of Distribution Bar = Clear Span (Lclear) + (2 x Beam Width) – (2 x Con. Cover) + (1 x Inclined Length) – (45° bend x 2)

= 6000 + (2*240) -(2*25) + 37.8 – (10*2) = 6447.8 mm or 6.45 m

Step 3 – Top Extra Rods

a) Number of Top Bars (Longer & Shorter Side)

- Number of Top Bars (Longer Side) = Crank Length (L/5)/ Spacing = (5400/5)/150 = 7.2 = 7 No.s x 2 side = 14 No.s

- Number of Top Bars (Shorter Side) = Crank Length (L/5)/ Spacing = (6000/5)/150 = 8 = 8 No.s x 2 side = 16 No.s

b) Cutting length of Top Bars (Longer & Shorter Side)

- Cutting Length of Top Bars (Longer Side) = 6000 + (2 x Ld) = 6000 + (2 x 40 x 10) = 6800 mm or 6.8 m

- Cutting Length of Top Bars (shorter Side) = 5400 + (2 x Ld) = 5400 + (2 x 40 x 10) = 6200 mm or 6.2 m

| Description | Dia of Bar | No of Bars | Cutting Length | Steel weight Per Metre |

Total Qty (Kg) |

| Main Bar | 10 | 41 | 5.85 | 0.62 | 148.71 |

| Distribution Bars | 10 | 28 | 6.45 | 0.62 | 111.97 |

| Top Bar (Shorter Side Extra Rod) | 10 | 16 | 6.2 | 0.62 | 61.50 |

| Top Bar (Longer Side Extra Rod) | 10 | 14 | 6.8 | 0.62 | 59.02 |

| Total | 381 Kg | ||||

Happy Learning 🙂

6 Comments

Hello, I need a clarification ,Whether every main bar should be cranked or alternative bar should be cranked .I saw somewhere mat of main bar and distribution bar are placed and crank bars are added. Kindly clear the confusion.

Hello Bharath, Every main bar should be cranked (one side of the reinforcement) and it would be placed opposite to each other. After placing, it looks like alternative bars only have been cranked.

While calculating Number of Top bars , already we are calculating both sides, again at the end why we are multiplying x2 sides ?

Hi Prakash, For two-way slabs, we provide top bars on four sides. On calculation, we have calculated two sides only that’s why we have multiplied it by 2.

Hello, I don’t understand the meaning and location of development length this item of 40d, please help me to make clear practically.

What is beam width in that case I don’t get it from where u take 240