The development of any particular area depends on the transportation facility of that area. Road transport plays an important role in the country’s infrastructural development.

Likewise, the coarse aggregate used in road structure plays a vital part in its strength.

We have already discussed the classification of aggregates earlier in detail to understand its origin. Now examine the resistance capacity of that aggregate.

Why do we conduct this test?

As you all know, road transportation facilities will always busy with live loads.

The constant movement

Due to massive load movement on it, the coarse aggregate will be subjected to constant pressure which will start disintegrating & disfiguring the road.

Therefore it is essential to check that the aggregate used on the road construction has sufficient impact bearing capacity & stability otherwise known as toughness.

What is the aggregate impact value test?

A relative measure of the resistance of aggregate due to the sudden shock or impact on it is called aggregate impact value.

Based on the impact value, we can decide whether the coarse aggregate is suitable for construction or not. This test is performed to ensure the aggregate toughness, which is used in road construction to work as a base layer, sub-base layer.

How do you calculate the aggregate impact value?

The impact value is measured in the ratio between the sieved aggregate of 10mm & 2.36mm aggregates. The aggregate impact value test will be conducted as per the Indian Standard Code IS code 2386 Part 4.

Let’s start with the experiment to understand the concept better.

Precautions to be taken

- The sample aggregate should be free from moisture.

- The sample aggregates must be cleaned by the cloth to free from dust.

- The tamping work should be executed in a gentle manner.

- Must wear a hand glove when the sample is taken out of the oven.

- The test should commence after the sample losses its heat after taken out from the oven.

- The hammer blowing should be done 15 times, not less than with a 1-second interval for each blow.

Apparatus Required

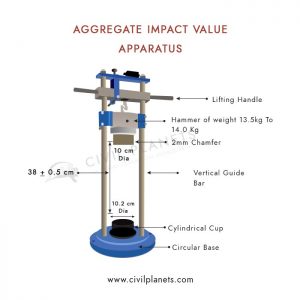

- Impact Value Testing Machine

- Tamping rod

- Weighing balance

- Oven

- Sieves 12.5mm, 10mm & 2.36mm as per IS standard

Procedure

- Step 1 – First, the aggregate sample sieve through 12.5mm sieve and collect it which is retained in 10mm sieve.

- Step 2 – Now, the sample should be dried through the oven up to 4 hours at 100 deg to 110 deg.

- Step 3 – Then, the aggregate sample should be filled in the metal cup by 3 layers. Each layer should be tamped 25 times by the tamping rod. Remove the excess sample from the metal cup.

- Step 4 – The net weight of the aggregate sample, which is in the metal cup, should be measured as W1.

- Step 5 – Now, the weighted sample filled in the metal cup and should be tamped gently.

- Step 6 – Then the metal cup is placed horizontally in the impact machine and locks it to ensure that it does not oscillate.

- Step 7 – Release the hammer of the Impact test machine, which falls freely on the sample. It should be done 15 blows at less than 1-sec interval.

- Step 8 – Then remove the metal cup from the machine & sieve the aggregate through 2.36mm sieve.

- Step 9 – Now weigh the collected samples as W2.

Result

Ratio of Impact Value = (W2/W1) x 100

This test must be done at least for two samples. The average value of the two samples is the Impact Value of Aggregate.

Lab Test Report Format

| SI | Description | Sample 1 in grams | Sample 2 in grams |

| 1 | Weight of dried sample (W1) | 340 | 360 |

| 2 | Weight of crushed particle passed through 2.36mm sieve (W2) | 50 | 65 |

| 3 | Impact value of Aggregate = (W2/W1) x 100 | 15% | 18% |

Conclusion

Average of Impact Value of Aggregate = 16.5%

Now the tested aggregates are passed to be used in construction work.

The recommend aggregate Impact value is given in the below table

| SI | Aggregate classification | Impact Value |

| 1 | Strong | 10% to 20% |

| 2 | Satisfactory | 20% to 30% |

| 3 | Weak | above 35% |

Test Illustration Video

Video Courtesy – NCTEL

The aggregate impact value lower than 50% not recommended for construction & it should be avoided at any cost.

Hope you’ve learned something useful. Happy Learning 🙂

3 Comments

I have really learnt a lot from this post, it’s well explained, thanks sir for this knowledge.

I have new knowledge….thanks for sharing

I have got new knowledge….thanks for sharing sir…