One of the confusing activities in construction is the removal time of the shuttering board!. Right?.

Let’s discuss in detail about the deshuttering time along with precautions.

Different materials are used to make the formwork such as plywood board, steel. Modern times plastic formworks are also in use. However, the deshuttering period will be the same regardless of the material used.

IS code for Shuttering Removal

The formwork removal for different types of concrete elements is specified on IS code 456.

Deshuttering time

The deshuttering period of different concrete elements is listed below.

| # | Types of Formwork | Formwork removal time after casting of Concrete |

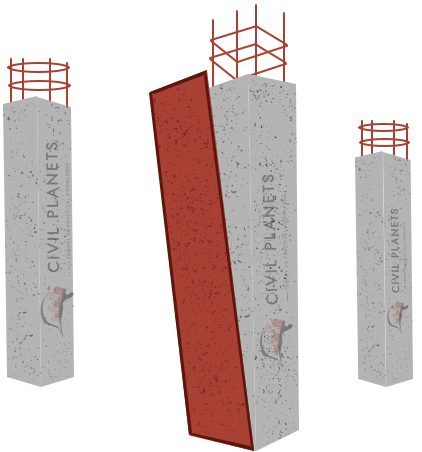

| 1 | Vertical Formwork of Column, beam, and wall | 16 Hours to 24 hours |

| 2 | Forms removal for Slab (Props has to be fixed immediately after removal of forms) | 3 days |

| 3 | Forms removal for Beams (Props has to be fixed immediately after removal of forms) | 7 days |

| 4 | Props removal for slab | |

| Span length up to 4.5m | 7 days | |

| Span length beyond 4.5m | 14 days | |

| 5 | Props removal for beams and arches | |

| Span length up to 6m | 14 Days | |

| Span length beyond 6m | 21 Days |

When should formwork be removed? (In terms of strength)

The formwork can be removed once the concrete attains at least twice the stress it may be subjected to at the time of removal.

In simple terms, the removal of the form is based on the maturity of concrete. The forms can be removed when the concrete gains its design strength by hardening and can resist the load occurrence on its own.

The concrete attains its compressive strength gradually, as mentioned in the table below.

| Days | Percentage of Strength |

| Day 1 | 16% |

| Day 3 | 40% |

| Day 7 | 65% |

| Day 14 | 90% |

| Day 28 | 100% |

Factors affecting the deshuttering time

The deshuttering period will be different when some special concrete and admixture is used.

The below factors affect deshuttering time.

- Grade of cement – The compressive strength value will vary between OPC 43 and OPC 53 and impact the percentage of strength gain. So the formwork removal period also differs.

- Temperature – In higher temperatures, the cement hydrates faster, and the concrete gets the strength quickly. But at the same moment, shrinkage cracks happen due to the fast hydrate of cement.

- Types of cement – Quick Setting cement and rapid hardening cement will attain greater strength in a short period than other cement types.

- Grade of concrete – A higher grade of concrete provides the ultimate strength in a short period, and it helps to remove the formworks at a minimum period.

Precautions during deshuttering

- Ensure to mention the date of concrete on the formwork (using wet chalk piece) so that we can instantly identify the time of removal.

- Proper curing of concrete makes it durable and helps to achieve greater strength. Ensure the concrete curing is appropriately done.

- While removing shuttering boards of a long-span slab, the prop should be provided for slabs, beams at the centre portion.

- If you see honeycombs on a concrete surface, immediately rectify it to avoid the corrosion in concrete.

- Proper supervision is required while removing the forms to ensure the quality of concrete.

- Ensure that there is a provision of necessary safety arrangements.

Happy Learning 🙂

1 Comment

Sir, give an example of complete design of a small building including footing, column, beam, slab etc. describing all inner components of building with all possible loads on them.

Because these componets effect the various load conditions and may affect the design. So also apply the factors of safety wherever it is required. Thus the frame structure should be well strengthened when ingradients of materials are fully and thoroughly mixed with suitable ratio or proportions as I think.