We know the importance of the Bar Bending Schedule and have already discussed it.

Here we are going to see the Bar Bending Schedule for Beam. It’s not totally different from slab calculation.

Before starting the topic make sure that you have read the below topics

- Why steel is used in Concrete?

- Bar Bending Shape Codes

- What is Development Length and Lap Length?

- Types of Stirrups in Reinforcement

We will discuss this scheduling topic as two parts, one for a typical beam and one for detailed design specification.

Let’s start.

Bar Bending Schedule for a Typical Beam

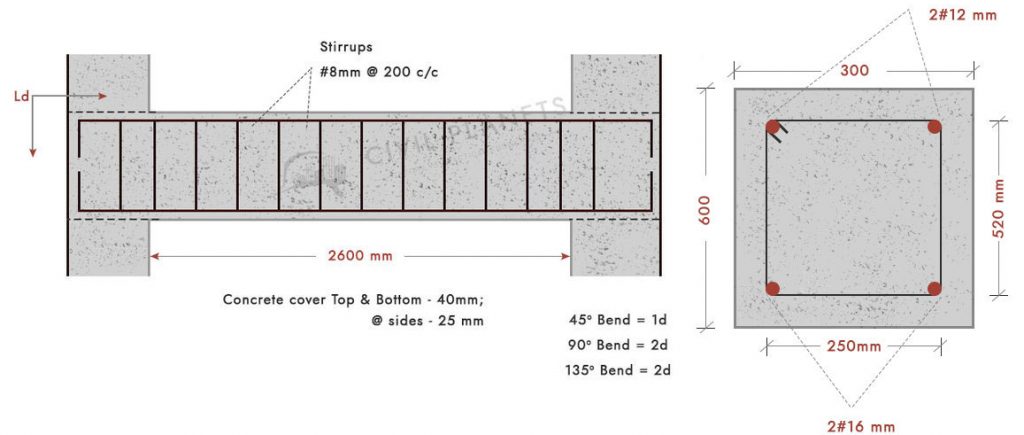

From the diagram, we can extract the below data

Given Data

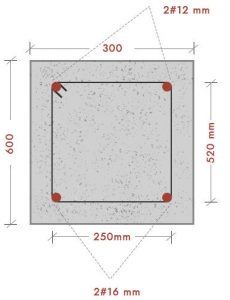

- Beam Size – 600 x 300 x 2600 mm

- Bottom Reinforcement 16mm of 2 numbers

- Top Reinforcement 12mm of 2 numbers

- Stirrups – 8mm of 200 c/c

- Concrete cover – 25 mm @ sides & 40mm @ top & bottom

- Development Length as 50d (assumption)

Step 1 – Find Cutting Length of Top & Bottom Bars

Cutting Length of Top Bar = Lclear + 2 x Development Length = 2600 + (2x50x12) = 3800 mm

Cutting Length of Bottom Bar = Lclear + 2 x Development Length = 2600 + (2x50x16) = 4200 mm

Step 2 – Find Number of Stirrups

Number of Stirrups = Lclear / Spacing +1 = 2600/200 = 13+1 = 14 Nos

Step 3 – Find Cutting Length of Stirrups

Cutting Length of Stirrups = Sum of total lengths (excluding cover) – 3 nos of 90° bends – 2 nos of 135° bends + 2 nos of Hook Length

We have a detailed post about cutting length of stirrups.

Assuming Length of one hook = 9d

Cutting Length of Stirrups = (520+250+520+250)-(3 x 2d)-(2 x 3d)+(2x9d) = 1540-(3x2x8)-(2x3x8)+ (2x9x8) = 1588 mm

Cutting Length of Stirrups = 1588 mm or 1.59 m

Bar Bending Schedule – Beam Format

| Description | Dia of Bar (mm) | Number of Bars | Cutting Length | Weight Per metre | Total Quantity (Kg) |

| Top Reinforcement | 12 | 2 | 3.8 | 0.89 | 6.764 |

| Bottom Reinforcement | 16 | 2 | 4.2 | 1.58 | 13.272 |

| Stirrups | 8 | 14 | 1.59 | 0.4 | 8.904 |

| TOTAL | 28.94 Kg | ||||

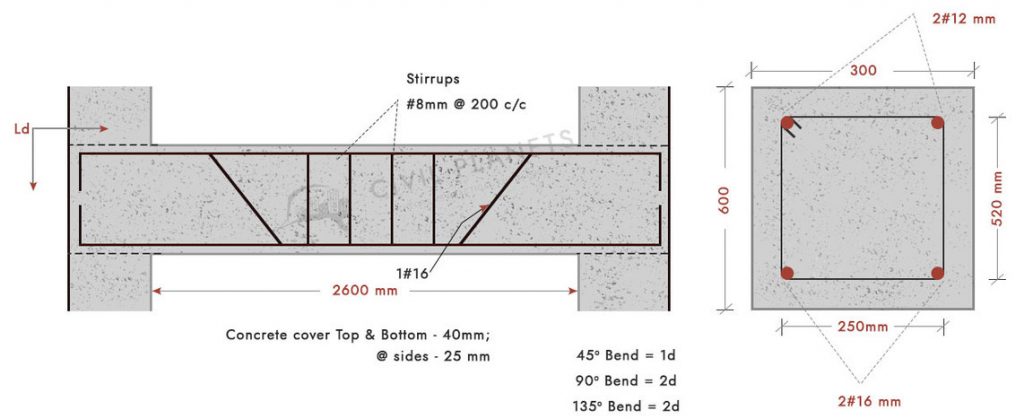

Bar Bending Schedule for Detailed Beam

Sometimes beams will come up with an extra one crank bar at the centre as shown in the diagram below.

From the diagram, we can extract the below data

Given Data

- Beam Size – 600 x 300 x 2600 mm

- Bottom Reinforcement 16mm of 2 numbers

- Crank bar at bottom reinforcement 16mm of 1 number

- Top Reinforcement 12mm of 2 numbers

- Stirrups – 8mm of 200 c/c

- Concrete cover – 25 mm @ sides & 40mm @ top & bottom

- Development Length as 50d (assumption)

Step 1 – Find Cutting Length of Top & Bottom Bars

Cutting Length of Top Bar = Lclear + 2 x Development Length = 2600 + (2x50x12) = 3800 mm

Cutting Length of Bottom Bar = Lclear + 2 x Development Length = 2600 + (2x50x16) = 4200 mm

Cutting Length of Bottom Crank Bar = Lclear + (2 x 0.42H)+ (2 x 45° bend) + (2 x Development Length)

Length of crank bar = 0.42 H

Where, H = Beam Depth – Concrete Cover – dia of bar = 600 – (2×40) – 16 = 504 mm

Cutting Length of Bottom Crank Bar = 2600 + (2×0.42×504) + (2x1d) + (2 x 50d)

= 2600 + (2 x 0.42 x 504) + (2 x 1 x 16) + (2 x 50 x 16) = 4655.36 mm or 4.66 m

Step 2 – Find Number of Stirrups

Number of Stirrups = Lclear / Spacing +1 = 2600/200 = 13+1 = 14 Nos

Step 3 – Find Cutting Length of Stirrups

Cutting Length of Stirrups = Sum of total lengths (excluding cover) – 3 nos of 90° bend – 2 nos of 135° bend + 2 nos of Hook Length

Assuming Length of one hook = 9d

= (520+250+520+250) – (3 x 2d) – (2 x 3d) + (2x9d) = 1540 – (3x2x8) – (2x3x8) + (2x9x8) = 1588 mm

Cutting Length of Stirrups = 1588 mm or 1.59 m

Bar Bending Schedule – Beam Format

| Description | Dia of Bar (mm) | Number of Bars | Cutting Length | Weight Per metre | Total Quantity (Kg) |

| Top Reinforcement | 12 | 2 | 3.8 | 0.89 | 6.764 |

| Bottom Reinforcement | 16 | 2 | 4.2 | 1.58 | 13.272 |

| Bottom Crank Bar | 16 | 1 | 4.66 | 1.58 | 7.363 |

| Stirrups | 8 | 14 | 1.59 | 0.4 | 8.904 |

| TOTAL | 36.30 Kg | ||||

Happy Learning 🙂