The aggregates are graded as fine and coarse aggregate based on the grain size. When the aggregate size is greater than 4.75mm is called coarse aggregate, and less than 4.75mm is called fine aggregate.

The sieve analysis test will do the grading of aggregates.

What is a sieve analysis test?

A test used to determine the particle size of fine and coarse aggregates is known as the sieve analysis test.

Collected sample aggregates are thoroughly sieved through appropriate IS Sieve to determine the particle size.

Why is a sieve analysis test important?

Well, concrete bonding will not happen when the same size of aggregates has been used in concrete, and it reduces the strength of the concrete.

Sieve Analysis test helps.

- To determine the quality of aggregates based on the size.

- Select the appropriate size of aggregates for particular construction work. For example, 40mm aggregates are used for PCC, and 12mm, 20mm aggregates are used in reinforced concrete works.

- To identify the flaky and irregular shape of aggregates, which is not suitable for construction works.

Methods of Sieve Size Analysis

The sieve analysis test has been carried out either by the mechanical, manual, or electrical method as per IS code 2386 Part 1.

Sample Preparation

The weight of sample aggregates is taken as per the below table. The sample should be clean and dried at 100°C to 110°C in the oven.

| SI | Maximum size of material present in substantial quantities | Weight to be taken for test in Kgs |

| 1 | 75mm | 60Kg |

| 2 | 40mm | 25Kg |

| 3 | 25mm | 13Kg |

| 4 | 19mm | 6.5Kg |

| 5 | 12.5mm | 3.5Kg |

| 6 | 10mm | 1.5Kg |

| 7 | 6.5mm | 0.75Kg |

| 8 | 4.75mm | 0.4Kg |

Apparatus Required

- IS sieve for Fine aggregates – 10mm, 4.75mm, 2.36mm, 1.18mm, 600 microns, 300 microns, 150 microns, and 75 microns.

- IS sieve for Coarse aggregates – 25mm,20mm 12.5mm, 10mm, 4.75mm.

- Weighing Balance

- Pan

Test Procedure

Fine aggregates

- Take a 1kg fine aggregate test sample.

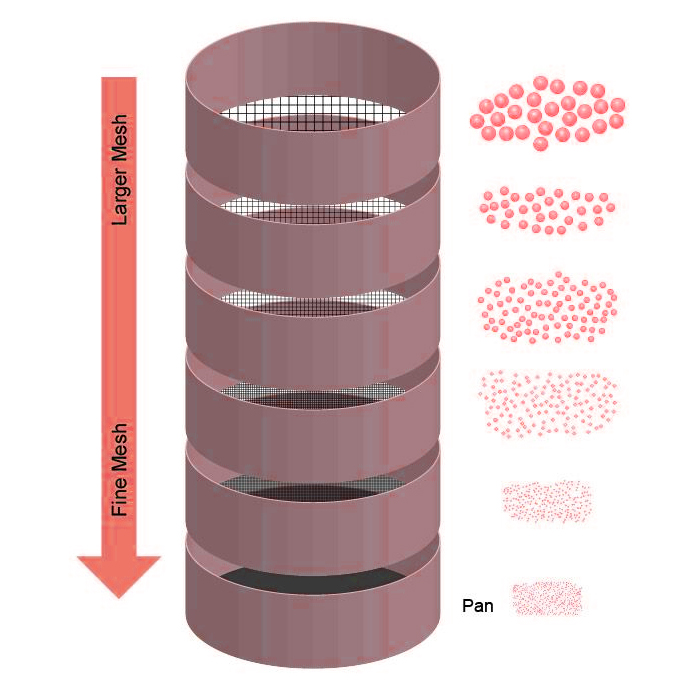

- Arrange the IS sive in descending 10mm, 4.75mm, 2.36mm, 1.18mm, 600 microns, 300 microns, 150 microns and 75 microns.

- Now fill the sample to the highest sieve and sieve well for up to 10 minutes.

- After completion of sieving, then weigh the aggregates retained in each sieve & note it down.

Coarse aggregates

- Take 1kg of the coarse aggregate test sample.

- Arrange the IS sieve in descending 25mm,20mm 12.5mm, 10mm, 4.75mm.

- Now fill the sample to the highest sieve and sieve well for up to 10 minutes.

- After completion of sieving, then weigh the aggregates retained in each sieve & note it down.

Lab Report

| Size of IS Sieve | Weight of Aggregate retained in Sieve | Retained sample in Percentage | Cumulative Percentage | Percent Passing | |||

| I | II | III | Avg | ||||

| D4 | |||||||

| D10 | |||||||

| D20 | |||||||

| D40 | |||||||

Calculation

- Soil retained on each sieve shall be calculated in percentage based on the total weight of the soil sample taken.

- Based on the result, a graph has to be plotted. Particle size will be mentioned on X-axis and percent finer mentioned on Y-axis. This graph is called the grading curve. Corresponding to 10%, 30%, and 60% finer, obtain diameters from the graph, designated as D1O, D30, and D60.

- The Coefficient of Uniformity (Cu) and the Coefficient of Curvature (Cc) will be calculated using the following equations: Cu = D60/ D10 Cc= D302/(D60 x D10)

Happy Learning 🙂

6 Comments

Lovely and well highlited

Good job…..

Now and later your new member who is on the track of learning more

Thanks brother you are doing a great job,

keep on doing it and for sure you will achieve great success in life

one more explanation about this please, wanna see it soon

Theory procedure is very simple method and understood easily

Request you please do more vedios in civil engineering subjects

Thank you