We know there are two concrete strength testing methods, such as destructive test method and Non-destructive method.

We use both methods to check the compressive strength and characteristic strength of concrete.

But both test methods can be applied to concrete cubes only after 28 days because the concrete requires proper curing to gradually attain its ultimate strength, as mentioned in the table below.

| SI | Days | Percentage |

| 1 | Day 1 | 16% |

| 2 | Day 3 | 40% |

| 3 | Day 7 | 65% |

| 4 | Day 14 | 90% |

| 5 | Day 28 | 100% |

In some special situations, the cube must be tested earlier to know the strength of concrete to proceed with the construction work without delay. The accelerated curing method helps to test and know the strength of the concrete specimen in earlier after concrete casting.

What is Accelerated Curing Test?

Usually, the concrete specimen shall be tested after completion of 28 days of concrete curing activity.

The accelerated curing test is a method of curing concrete specimens to attain its yield strength quickly. So, we can know the 28 days of compressive strength of concrete within a day.

Why do we need it?

- Most of the time, knowing the concrete strength earlier helps avoid dangerous accidents and saves a life.

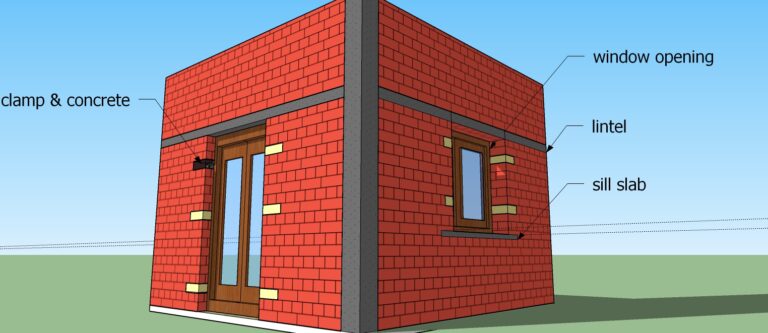

- This Accelerated curing method is mostly used in the precast construction industry, where the formwork needs to be removed at the earliest for productivity.

- To reduce the waiting period of formwork removal and to save cost eventually.

How do you accelerate the curing of concrete?

The acceleration concrete curing can be done by following methods,

- Warm water method

- Boiling water method

We discuss the boiling water method, which is mostly used as an accelerated curing method.

Apparatus required

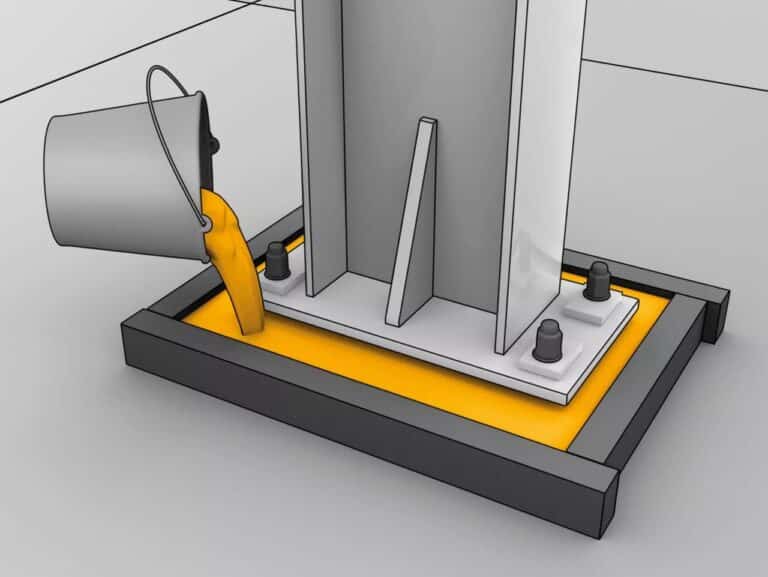

- Curing Tank

- Clock

- Compression Testing Machine

- Weighing Machine

- Cube Mould

IS code for Accelerated Curing Tank

The specification of the accelerated curing tank has been mentioned in IS code 9013. The curing tank should be made of corrosion-resistant material.

The internal size of the curing tank should be accommodating the concrete specimens with sufficient water for immersing. The temperature of curing water should be controllable.

Test procedure of the Boiling Water Method

- After the preparation of a concrete specimen, it should be kept free from vibration in natural moist air at the temperature of at 27 +/- 2°C for 23 hours +/-15 minutes.

- Now the specimen should be placed gently in the curing tank up to complete immersion for 3.5 hours +/- 5 minutes.

- Now, let the water boil at 100°C after placing the specimens, and the temperature of the water should not be dropped more than 3°C.

- After completion of the curing period, remove the mould of the specimen and place it in a cooling tank at 27 +/- 2°C for 2 hours.

Test Results Calculation

- Now the age of the concrete cube when testing should be 28.5 hours +/- 20 minutes.

- Now the specimen tested through the compressive testing machine and note down the crushing value in N/Sqmm.

- Anticipated compressive strength of concrete in 28 days R28 = 8.09 + 1.64 Ra.

Ra – Crushing value of accelerated concrete cube and the 8.09 is a constant value derived by correlating the test results of normal and accelerated concrete curing methods.

Lab Report

| Date | Size of Specimen | Weight in Kgs | Time of water adding to the ingredients | Time of immersion of specimen in curing Tank | Crushing Value | R28 |

| Sample 1 | ||||||

| Sample 2 | ||||||

| Sample 3 |

Safety Precaution

- The specimen should be free from dust and other impurities.

- Make the specimen at a proper mix ratio.

- Must wear hand gloves while handling the curing tank.

- The curing tank water should be refilled periodically to avoid the formation of impurities.

Happy Learning 🙂