The formation of cracks on the concrete surface may lead to reduce the durability of the concrete. The crack may form in a short period, or it may take a few years, but it will cause the structure to be too severe.

What is Grouting?

Grouting is a process of injecting dense fluid into cracks or cavities to fill the gaps in structural works such as concrete, masonry, other non-structural works such as tiling.

The grout is the mixture of paste that contains cement, sand, chemical & a certain quantity of water which can be injected to seal the cracks or pothole.

Applications of Grouting

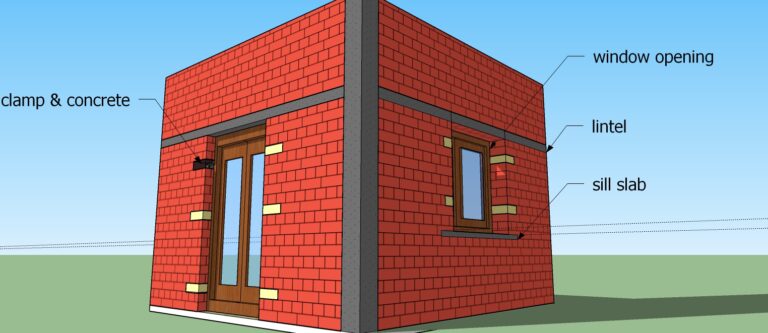

The grout is used to seal the crack and used in tile flooring work to fill the gap between the tiles, filling the gaps for waterproofing and soil stabilization.

- Used to repair the defects in masonry

- Used to fill and repair the cracks in concrete

- Used to fill the gaps between rock face and tunnel lining works

- In prestressed concrete construction, grout will be used to fix tendons.

- In the concrete pile wall, grout will be used to fix the ground anchors.

Types of grouting based on material

Grouting will be classified as below using their core materials

- Bituminous Grouting

- Chemical Grouting

- Cement Grouting

- Resin Grouting

- Bentonite Grouting

Types of grouting based on applications

Types of grouting can be classified as below.

- Types of grout used for structure work

- Types of grout used for tile laying work

Types of grout used for structural work

G1 Grouting

The strength of the G1 type grouting will be around & not less than 30 N/Sq Mm in 7 days and 40 N/Sq Mm in 28 days. Mostly this type of grout is used in steel structures such as tower erection work, ships.

G2 Grouting

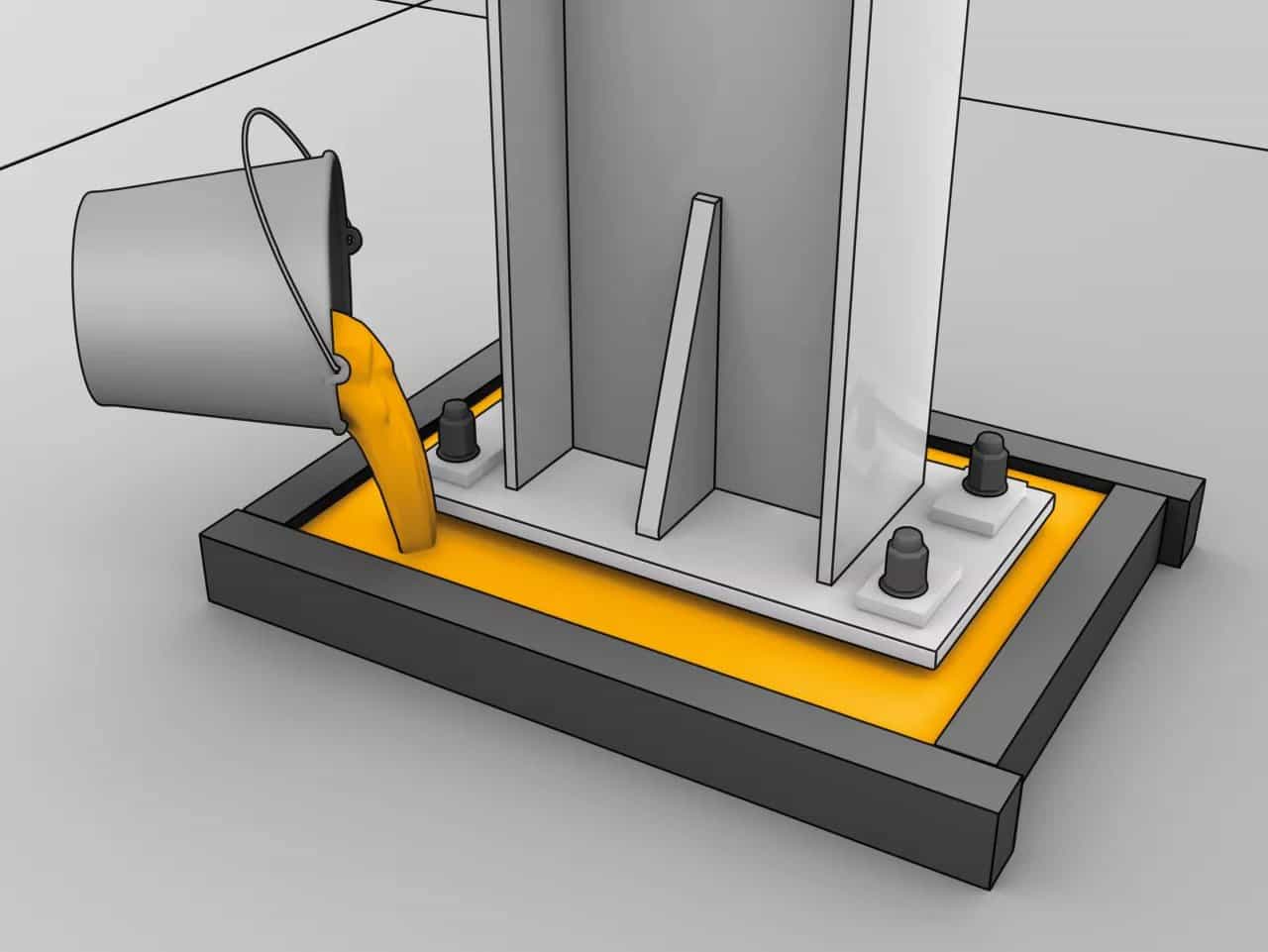

The G2 grout compressive strength should be 50 N/mm2 in 7 days and 60 n/mm2 in 28 days and used to construct the prefabricated structure and other heavy machinery erection work subjected to vibrations. The gap between the base plate and the pedestal has been filled by the grout, which can arrest the vibration.

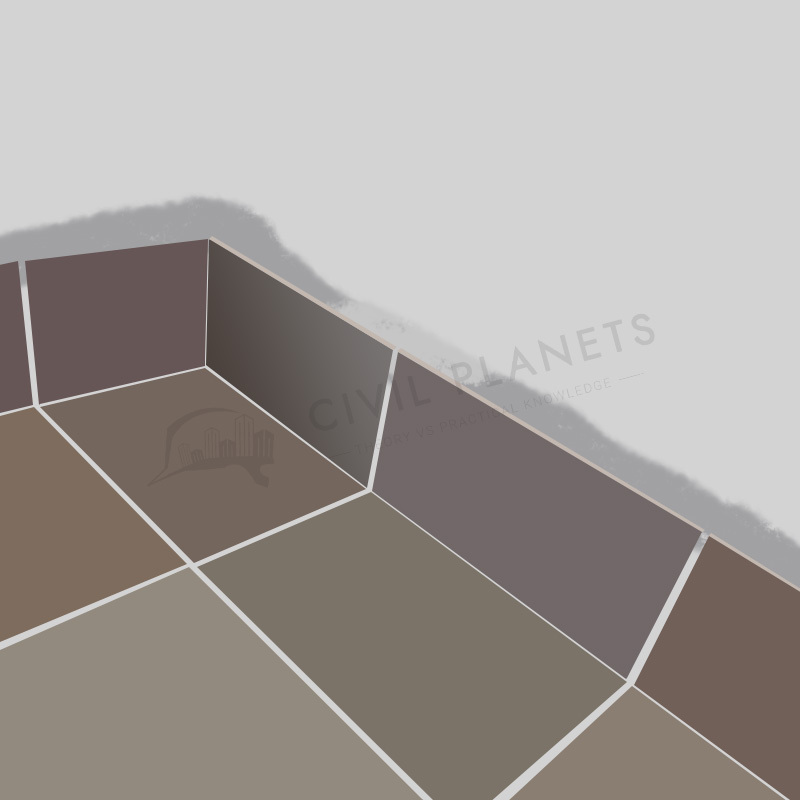

Types of grout used for Tile Flooring work

Un sanded & Finely sanded grout – The un sanded grout & finely sanded ground were used in wall tile laying work where the filling gap between 3mm to 9mm.

Cementitious grout – Cementitious grout is the combination of cement and sand used to fill the flooring tile gap. Also, it is used to seal cracks that happen in concrete surfaces.

Epoxy grout – The epoxy grout manufactured by chemicals such as resins, polypropylene and curing compounds. The epoxy grouts are costlier than other grout types, but it is much stronger and prevents the moisture penetration into the concrete surface.

Application of Grouting – How to do grouting?

The application of grouting is simple and easy. The grouting material is available in a powder liquid state.

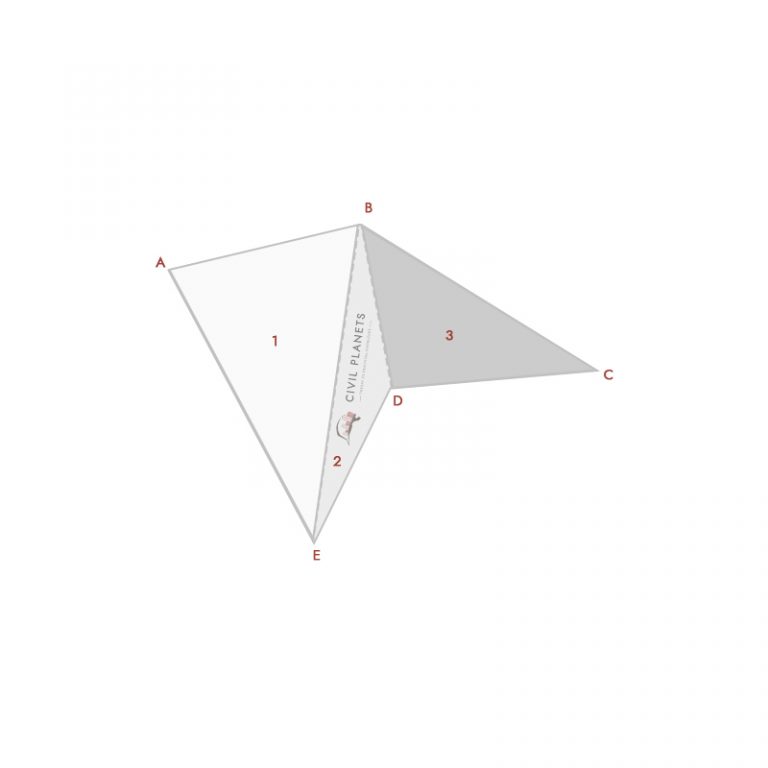

For example, if we are going to apply cementitious grout, then first measure the grout’s required volume. Now take a certain quantity of cement and add water as required workability, and mix well. Then pour or inject the grout into the crack surface or the cavities gently.

Advantages of Grouting

- It can resist the vibration that passes to the foundation.

- It prevents water penetration, seepages.

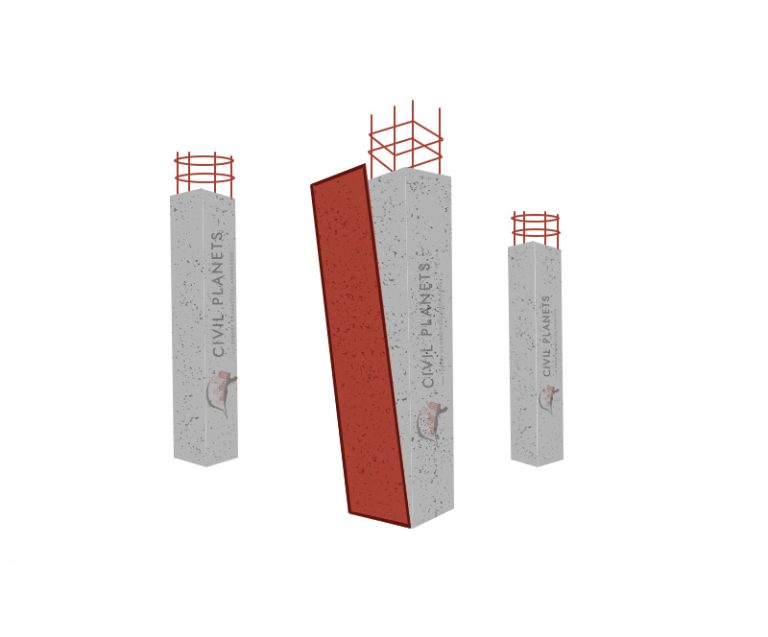

- It is used in stub column construction.

- No skilled manpower required.

- The application of grouting is very simple.

- The grouting material is available in either powder or semi-solid state.

- It is stronger against compressive strength.

- The grout material is economical compared to other types of repair work.

- Attains the hardened state in a short period & dry quickly.

Happy Learning 🙂

2 Comments

I love too be the member of this civilplanet,construction am a Manson in my country here in Nigeria but I wish too learn more and more,,pls take me in cos I love to be an civil engr.

I am civil engineer here in my country nigeria, an am happy to see myself here as a member thanks.