Mostly for small house construction, the reinforcement will be calculated just based on the thumb rule. The excess procured steel will be used for other works.

But for a large-scale project, the tedious BBS schedule will be prepared to avoid the unnecessary wastages.

Bar bending shape codes are the cutting length formula used to avoid unnecessary cut wastes on reinforcement.

Advantages of using BBS codes in BBS Schedule

- To minimise the wastage

- To cut the steel bar easily based on the shape code

- To procure the accurate quantity of material

Contents of the Article

show

Standard Bar Bending Shape Codes

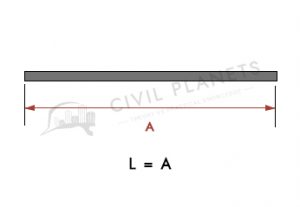

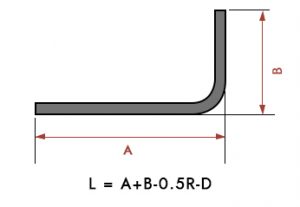

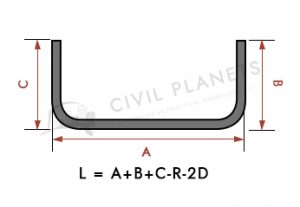

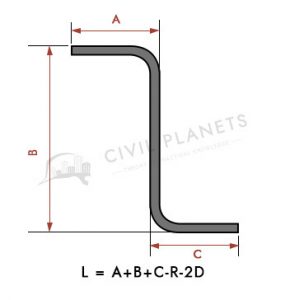

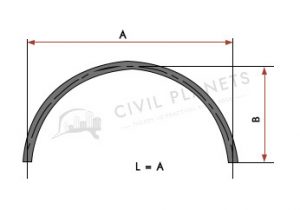

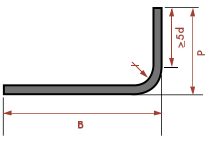

| Bar Bending Shape | Cutting Length of Bar |

|

L = A |

|

L = A+B-0.5r-d |

|

L = A+B+C-r-2d |

|

L = A+B+C-r-2d |

|

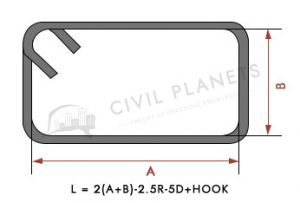

L = 2(A+B)-2.5r-5d+Hook |

|

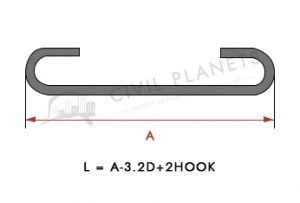

L = A-3.2D+2Hook |

|

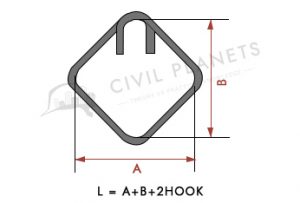

L = A+B+2Hook |

|

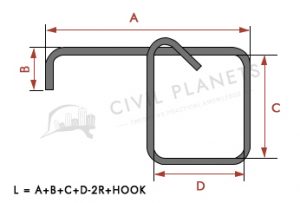

L = A+B+C+D-2r+Hook |

|

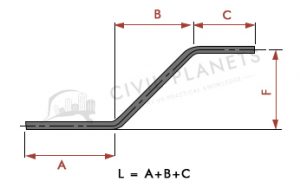

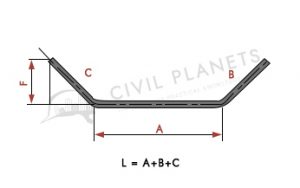

L = A+B+C |

|

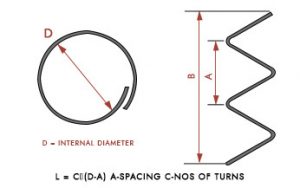

L = Cπ(d-A) A-Spacing C-Nos of turns |

|

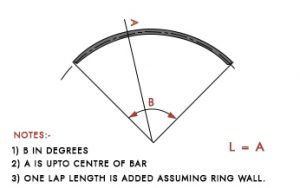

L = A |

|

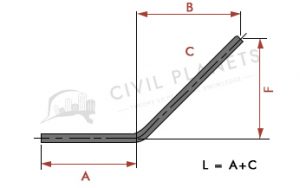

L = A+C |

|

L = A+B+C |

|

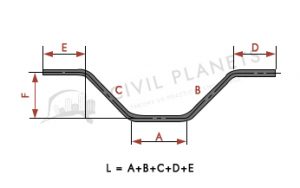

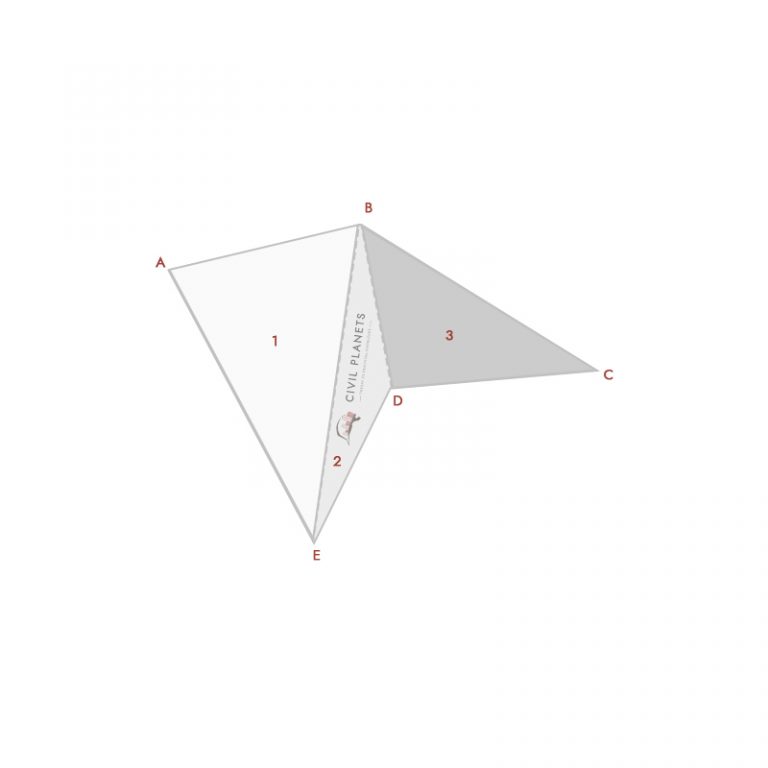

L = A+B+C+D+E |

|

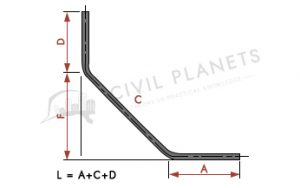

L = A+C+D |

|

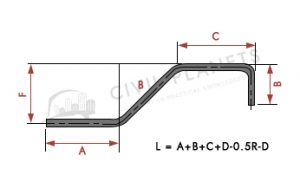

L = A+B+C+D-0.5r-d |

|

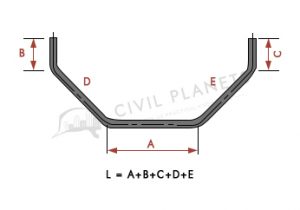

L = A+B+C+D+E |

|

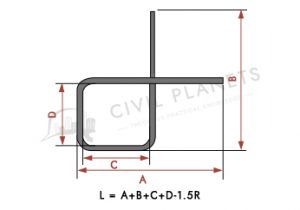

L = A+B+C+D-1.5r |

|

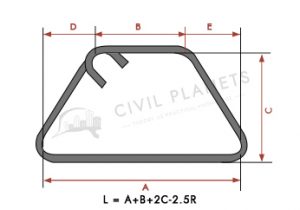

L = A+B+2C-2.5r |

|

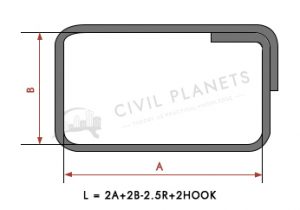

L = 2A+2B-2.5r+2Hook |

|

L = A |

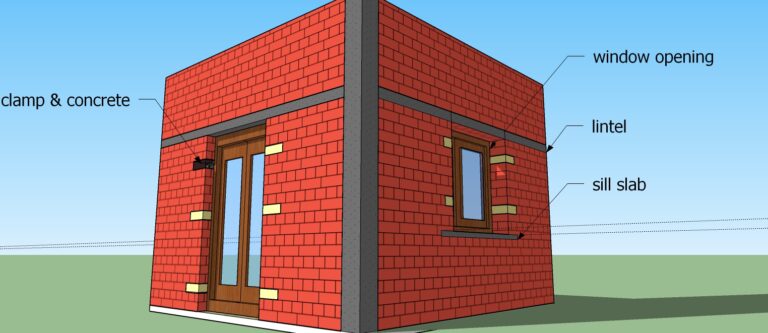

Notes:-

- The end or side covers for steel bar may be taken as 4cm to 5cm

- The bottom & top covers should be in the range of 1cm to 2cm.

- The covers for beam shall be taken as 2.5cm to 5cm.

- The length of one hook is 9 dia of the bar but not less than 75mm.

Minimum Scheduling Radius, Diameter, and Bend Allowance

| Nominal Size of Bar (d) | Minimum Radius for Scheduling (r) | Minimum Diameter of Bending | General (min 5d straight), including links where bend >150⁰ | Links Bend <150⁰ |

| 6mm | 12 | 24 | 110 | 110 |

| 8mm | 16 | 32 | 115 | 115 |

| 10mm | 20 | 40 | 120 | 130 |

| 12mm | 24 | 48 | 125 | 160 |

| 16mm | 32 | 64 | 130 | 210 |

| 20mm | 70 | 140 | 190 | 290 |

| 25mm | 87 | 175 | 240 | 365 |

| 32mm | 112 | 224 | 305 | 465 |

| 40mm | 140 | 280 | 380 | 580 |

| 50mm | 175 | 350 | 475 | 725 |

2 Comments

Very Good Guidance for The Preparation Bar Bending Schedule and Rebar Fabrication Works.

Excellent.. Love the easiness you provided for bbs..