What is the Charpy impact test used for?

The Charpy impact test used to determine the resistance capacity of metal (steel) specimen against sudden impact load of a pendulum which swung from a certain height.

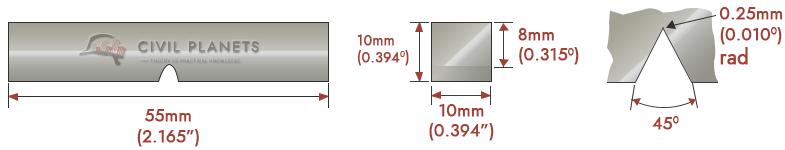

The other name of the Charpy impact test is the Charpy V-notch test because of the specimen used in this test cut at a certain depth in ‘V’ shape.

What does the Charpy impact test measure?

The Charpy impact test is performed to measure the required amount of energy to break a metal piece by the force of pendulum weight.

Importance of impact test

- The primary purpose of performing this experiment is to find whether the material is brittle or ductile.

Materials that break without plastic deformation (no energy absorption) is known as a brittle material. Material breaks with large plastic deformation (little energy absorption) are known as ductile material.

- It is a way of measuring the toughness of material and quantity of energy absorption during its fracture.

Apparatus Required

- The specification of the test specimen and methodology has been mentioned in IS code 1757.

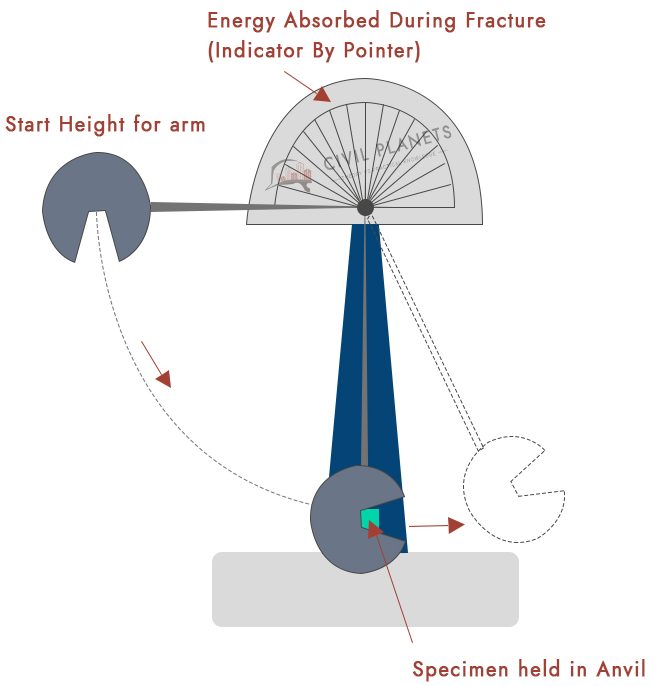

- Charpy Machine – a heavyweight, would be attached in the pendulum swing machine.

- Metal Specimen as Per IS standard.

Test procedure

Specimen Preparation

The size of the sample should be 55mm x 10mm x 10mm and should have a depth of 2mm notch at centre.

- Lift the pendulum to its starting position. Then you have to check whether the test machine has been adjusted correctly.

- Initially, the Charpy machine has to be calibrated. To do this turn the dial gauge to the en value(highest value measurement) and release the pendulum without placing the specimen. The needle now goes to the starting value 0. Hence the Charpy machine is ready for the test.

- Now place the test specimen on the machine at the correct position by using the centring device.

- Then turn the dial gauge indicator needle downwards at the end value and release the pendulum.

- Now the pendulum swings down and cuts the specimen.

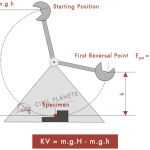

- Due to the energy absorption by the specimen, the pendulum does not attain the full height on the other side. Refer to the below pic.

- Using the dial gauge, we can measure the amount of energy absorbed by the specimen (in terms of Joules or Nm). Note down the value from the dial gauge.

Test formula

The amount of energy absorbed by the test specimen to break is called Knotch impact energy.

The Knotch Impact Energy KV = mgH – mgh

m – Mass of the Pendulum

H – Height of Pendulum starting point

g – Gravity

h – Height of the pendulum from the first reversal point

Lab report

The test has to be applied on a minimum of three specimens from the same batch.

| Specimen | Impact energy in Joules |

| Sample 1 | |

| Sample 2 | |

| Sample 3 |

The test is conducted to find whether the material is brittle or ductile. The brittle material absorbs less amount of energy, and ductile material absorbs large amounts of energy.

Factors Affecting Charpy Impact Energy

- Yield Strength – High yield strength metal will absorb less impact energy.

- Notch – The shape and depth of the notch should be made accurately. The improper notch will show the error value of energy absorption.

- Temperature – The test should be executed at the 23°C +/- 5°C. Higher temperature affects the ductility

Happy Learning 🙂

1 Comment

It’s really assume sir…Very well written…well understood..and the way of presentation is superb sir