Plum concrete is a normal concrete mix with large size stones of up to 300mm as inert fillers. Aggregates above 160mm are known as plums. The extended use of plum (boulders) saves PCC’s cost up to 30% and results in the apparent yield of concrete for a given amount of cement is increased.

Unlike reinforced or prestressed concrete, it is not reinforced with steel. Plum Concrete mix ratio will be up to M15, with use of boulders up to 300mm (60% concrete + 40% boulders). It is widely used as surface fillers under the foundation where the surface is uneven and sloped.

Purpose of Plum Concrete

- To attain the required surface level, the plum concrete will be placed under the foundation or footing.

- If the thickness of PCC needed is excessive and very large then to reduce the cost of PCC, plum concrete will be used.

- Mainly used in mass construction such as bridges, gravity dam, Side slopes of the embankment.

For Example, consider in the proposed site, there is a small area where the ground level is too sloped, and you can’t fill the area with soil. In that scenario, pluma concrete would be used as filler material.

How to calculate Plum concrete?

As you can see from the purpose section, it is mainly used to level the surface. So, the plum concrete calculation is 60% of M10 or M15 concrete mix and 40% of boulders.

Plum concrete should be laid layer and should not exceed 900mm in thickness. You can refer IS Code 456 (2000) Clause 5.3.3 for plum reference.

Process of Plum Concreting

There are seven steps in plum concreting.

- Levelling & Cleaning the surface – The proposed area should be cleaned and levelled. If low bearing soft soil is present, then it should be removed from the site.

- Wetting the Surface – Surface area should be wetted by spraying water to make the bonding strong between plum concrete and ground surface. Sometimes the termite resistant will also be added—anti-termite treatment.

- Material Inspection – Boulder should be strong, not flaky. It should be free from dust by washing properly.

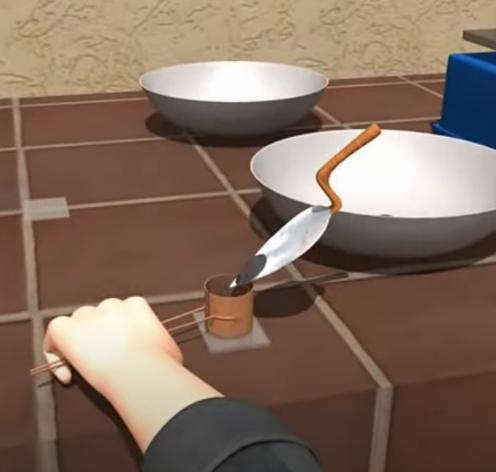

- Boulder’s Placement – As shown in the picture, the boulders will be placed in layers with sufficient gaps. The gaps should be less than 150 mm.

- Concrete placement – Now the concrete will be poured over the boulders, which slowly spread between the gaps.

- Repeat – Once the concrete is spread evenly, again boulders will be placed and then concrete, the process will continue until the surface attains the required level.

- Curing – Curing should be done for a minimum of 7 days. After that, the concrete will be moisturised by using jute bags.

Difference Between PCC Concrete and Plum Concrete

| Plain Cement Concrete (PCC) | Plum Concrete |

| Used as a protective layer for RCC Footings from water entrainment | Used to level the surface mostly |

| To support the formworks of RCC. | Used to achieve economic benefits |

| To avoid moisture entering the RCC structure and to prevent the corrosion of concrete. |

Plum Concrete Specifications

- Boulders used in the plum concrete should be 200-300 mm

- The plum should have at least 100 Kg/Sq Cm crushing strength value

- The concrete nominal mix should consist of aggregates up to 25mm.

- The plum volume should not exceed 40% of the concrete volume.

- The gaps between the plums should be less than 150 mm.

Uses & Application of Plum Concrete

- It is used to level the surface area when there is a deep slope or uneven surface

- It is used to construct the side slope for embankment

- It is used to level the surface of water channels (under)

Happy Learning 🙂

2 Comments

Volume of plums is 20 percent of volume of Concrete As per IS:456 (2000) Clause no. 5.3.3.

Please Update It

20% Volume of plums per total volume of concrete is for (PCC) plain concrete work only.