We knew that pipes are used to transport gas or liquid substance from one place to another place.

Different types of pipes such as steel pipe, PVC, uPVC, and RCC pipes are used in water transportation and PSC (Prestressed Concrete Pipe) pipe is one among them. The selection of pipe is based on the purpose, location, workability, and required durability.

The prestressed concrete pipes (PSC) usage evolved in recent years and replaced the conventional pipes such as RCC pipe, Steel pipe based on both strength and cost.

What is a PSC pipe or Prestressed Concrete Pipe?

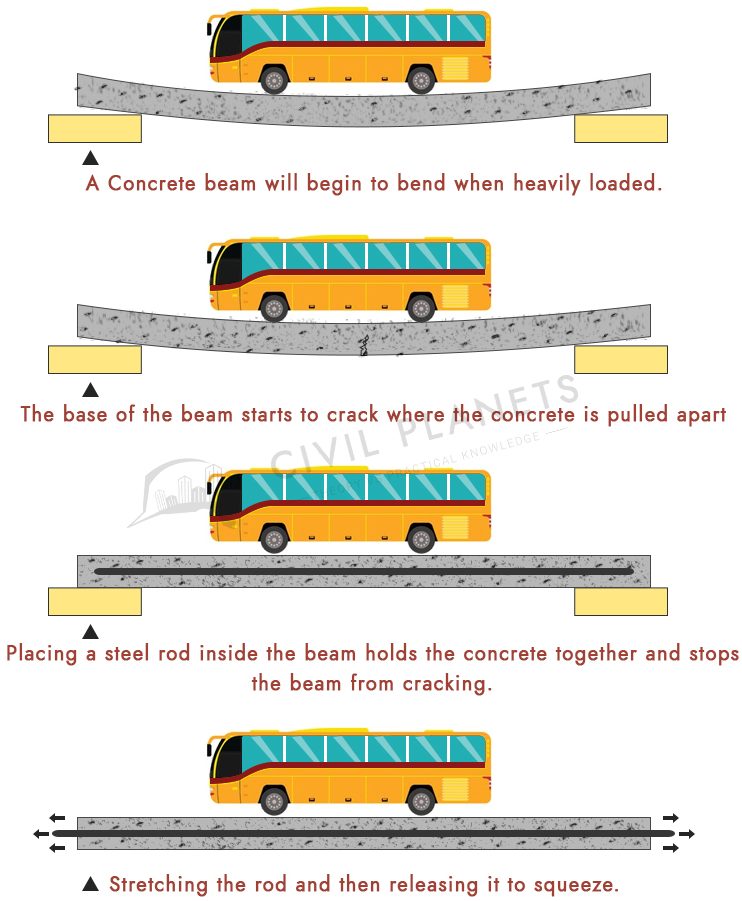

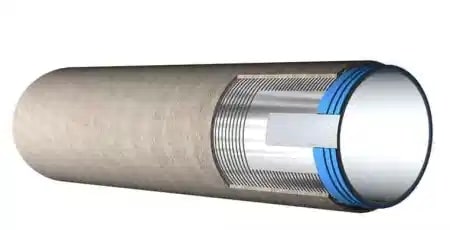

Prestressed Concrete Pipes are commonly used large diameter pipe manufactured by concrete and the high tensile steel wire which is helically placed around the concrete core under specific tension that gives tensile strength to the pipe.

The concrete is strong against compression force and weak against tension force so steel is placed around the concrete core to make it strong against both compression and tension force.

Which grade of concrete is used in reinforced concrete pipes?

The grade of concrete depends on the strength required for the specific work and M15 is the minimum grade of concrete used for manufacturing the reinforced concrete pipe.

Types of prestressed concrete pipes

The prestressed concrete pipes are classified as mentioned below.

- Prestressed concrete-lined cylinder pipe

- Prestressed concrete noncylinder pipe

Prestressed concrete-lined cylinder pipe

In this type, a helix of high tension prestressed steel wire placed around the concrete core, and a certain thickness of cement mortar placed to cover the steel wire. The steel joint rings are provided at both ends of the pipe for connecting to other pipes.

Prestressed concrete noncylinder pipe

In this type, a helix of high tension prestressed steel wire is placed around the concrete core by both longitudinal and circumferential directions, and the cement mortar coat placed over the wire wrap for protection.

IS code for PSC

The manufacturing specification of prestressed concrete pipe has been mentioned in IS code 784. The selection of the right material for manufacturing and quality, strength testing method also specified in that.

Uses of PSC pipes

The PSC pipes are majorly used for water transportation systems where high pressure of water is supplied.

- The PSC pipes can sustain high pressure of water flow so it is mainly used in drinking water and lift irrigation systems.

- Used in the gravity sewer system

- Used in sewage water disposal instead of stoneware pipe.

- Used in industrial sewage disposal

- Used as a culvert in the roadway due to its high strength.

Advantages of prestressed concrete pipes

- It is very economical compared to other types of pipes.

- PSC pipes are very hard so normal backfilling is sufficient.

- No special machinery or tools required for installation.

- The maintenance cost is low.

- The laying procedure is very simple and does not require very skilled manpower.

- It is impermeable so it does not affect the groundwater.

- The pipe-laying work can be completed fast due to its ease of workability.

Happy Learning 🙂