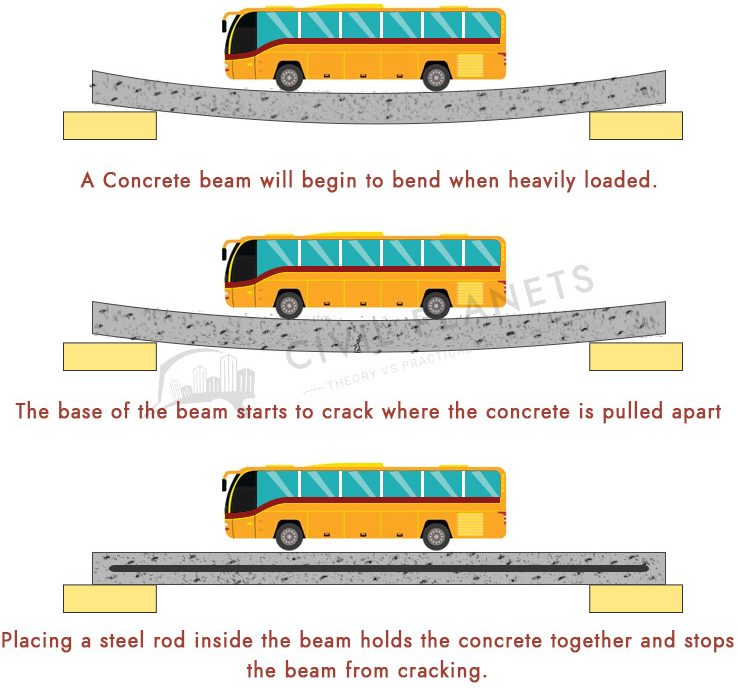

Yes!… The steel contains high tensile strength, and that’s why it is prefered in concrete. However, not every steel provides the same yield strength. It differs based on its constituents.

| Constituent | Fe 415 | Fe 415D | Fe 500 | Fe 500D | Fe 550 | Fe 550D | Fe 600 |

| Carbon | 0.3 | 0.25 | 0.3 | 0.25 | 0.3 | 0.25 | 0.3 |

| Sulphur | 0.06 | 0.045 | 0.055 | 0.04 | 0.055 | 0.04 | 0.04 |

| Phosphorous | 0.06 | 0.045 | 0.055 | 0.04 | 0.05 | 0.04 | 0.04 |

| Sulphur and Phosphorous | 0.11 | 0.085 | 0.105 | 0.075 | 0.1 | 0.075 | 0.075 |

What is a tension test on mild steel?

The tension test is applied on a certain length of metal piece for each unit of steel batch to know its tensile strength. Apart from the tensile strength, the young’s modulus, ultimate tensile strength, will also be calculated.

Why is it important?

Based on the tensile strength value, the steel will be graded. Difference between Fe415 & Fe500 Steel.

Fe denotes the symbol of iron (chemical element), and the number nearby represents the tensile stress of that steel. So if it is mentioned as Fe415, then we know that the iron has 415 N/Sq mm of tensile strength.

The tensile strength is one of the essential properties of steel. Apart from that, the other steel features, such as modulus of elasticity, yield strength, failure, or breaking point, also play a vital role in the strength of steel.

The tension test on steel ensures that the steel has every below-mentioned properties to withstand the structural loads.

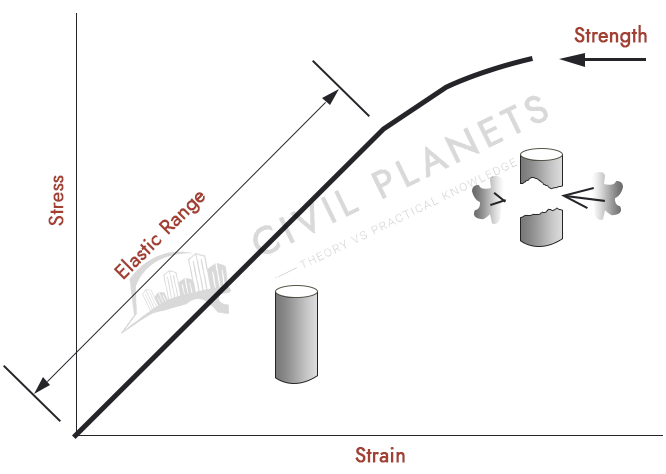

- Yield strength – The starting point of steel rod deformation by applying stress is called yield strength.

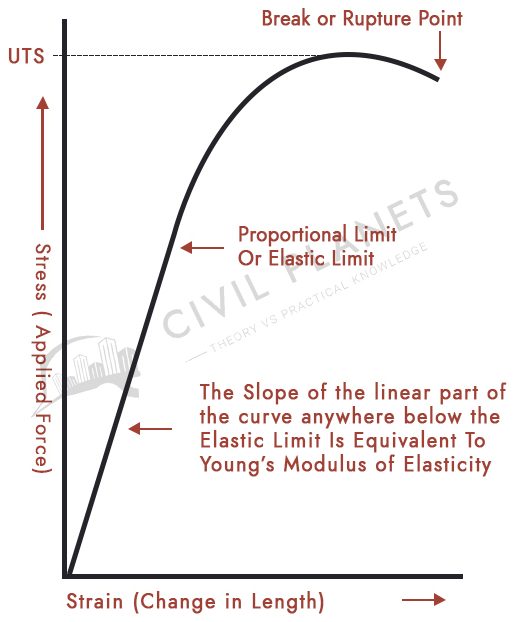

- Modulus of elasticity – Measurement of material stiffness is known as the modulus elasticity. The ratio between stress and strain is called the modulus of elasticity or Young’s modulus.

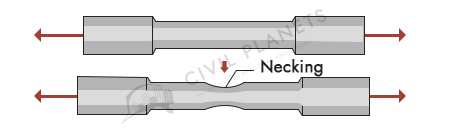

- Failure or Breaking Point of Steel – The steel rod starting to break due to the load occurrence is called the failure or the breaking point of steel.

Equipment for Tension test

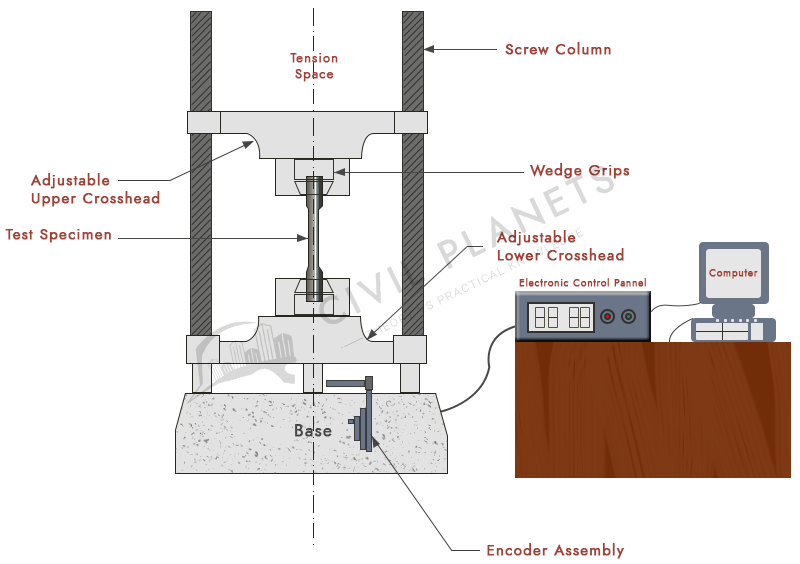

- Universal testing machine – It consists of two components, such as loading and control panel.

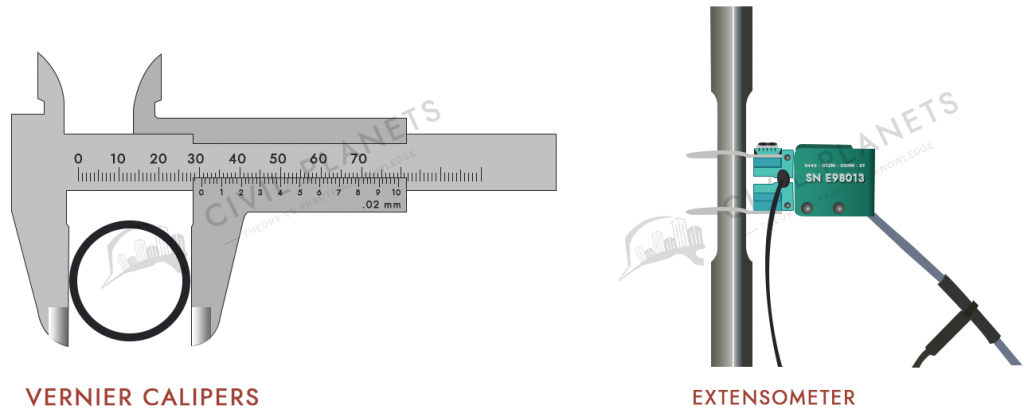

- Extensometer – Used to measure the deformation of a metal element.

- Vernier Caliper – Used to measure the elongation length of the steel.

- Punching tool – Used to mark the gauge length of the steel specimen.

Test Procedure

The tension test on mild steel executed as per the IS code 1608.

- The steel specimen should be cleaned and must be threaded at both ends before placing it. The gauge length is marked by a punching tool.

- Now place the steel specimen on the testing machine and connect the extensometer in the right position.

- Choose the parameters which have to be tested through the computer that is connected to the machine.

- Now apply the tensile stress gradually on the steel specimen.

- It starts to deform, which has to be noted down as the yield point.

- Due to the stretching of the steel rod, its length will be increased from its original length, called elongation of the steel rod.

- After a specific limit of stress, the rod will break, and it is called the ultimate Load.

- We can get all parameters to determine the tensile strength of the steel rod from the computer, which is already connected to the machine.

Tension test on mild steel graph

Test Concept

Based on the steel specimen’s test result, its properties such as yield point, breaking point, and ultimate point data will be plotted as a graph.

- Modulus of Elasticity, E = Stress/Strain[This is calculated within the elastic limit. The slope of the stress-strain curve provides the modulus of elasticity]

- Stress = Applied Load/ Cross sectional Area

- Strain = Elongation length / Original length

- Yield Stress = Load at yield Point/Original C/s Area

- Ultimate Stress = Ultimate Load/Original C/s Area

- Nominal Breaking Stress = Breaking Load/Nominal Breaking Stress

- Actual Breaking Stress = Breaking load/Neck Area

- Percentage elongation = (Change in length/Original Length)/100

- Percentage reduction in the area = (Change in length/Original Area)/100

Lab Results

| Specimen | Dia of Steel bar in mm | Young’s Modulus in N/Sqmm | Yield stress N/Sqmm | Ultimate stress N/Sqmm | Nominal Breaking stress N/Sqmm | Actual breaking stress N/Sqmm | Elongation in % | Reduction of Area in % |

| Sample 1 | ||||||||

| Sample 2 | ||||||||

| Sample 3 |

Happy Learning 🙂

1 Comment

Thanks