We all know the strength of concrete depends upon many factors such as properties of construction material, Mix Ratio & Working conditions.

Workability of concrete is face value for all these factors. A single value that indicates the overall strength of concrete.

Here we are going to discuss the importance of Workability of concrete.

- What is the workability of concrete?

- Factors affecting workability

- What are the various tests on the workability of concrete?

- How do u measure the workability of concrete?

What is the workability of concrete?

Workability is a property of concrete.

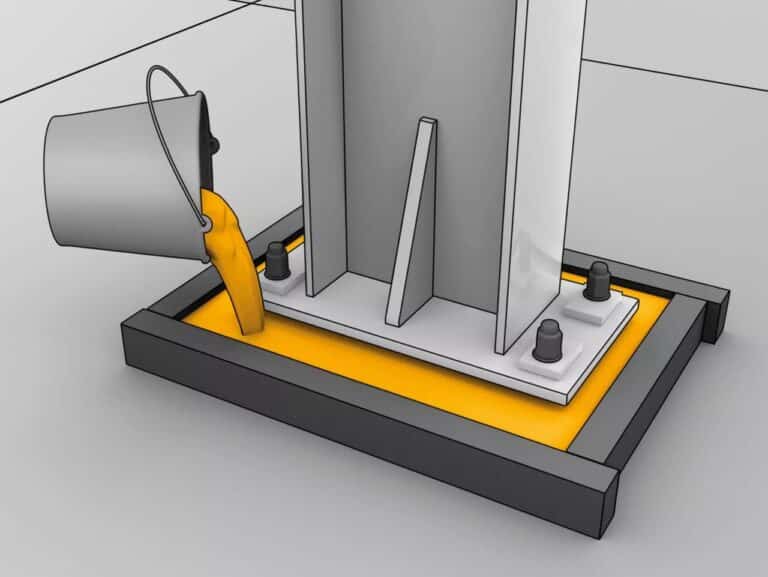

In simple terms, concrete workability means the ease of fresh concrete which can be mixed, placed and compacted fully over the formwork without concrete segregation (Honeycomb) & bleeding.

Proper Guidance has been given in IS Code 1199-1959 (Complete IS Code List) for concrete workability.

| Conditions | Degree of Workability |

| Shallow Sections | Very Low |

| Mass Concrete & Light reinforced sections slab, beam & column | Low |

| Heavy Light reinforced sections slab, beam & column | Medium |

| Trench fill, In-situ piling, Tremie concrete | High & Very High |

How easily you can handle the concrete determines its types as

- High workability

- Medium workability

- Low workability

Factors affecting workability

Workability of concrete is directly proportional to

- Aggregate Cement Ratio

- Water content

- Properties of aggregates

- Types of Cement

- Environmental Factor

- Type of construction work

- Use of Admixture

Aggregate Cement Ratio

As you know Cement is a vital ingredient in concrete which acts as a glue between aggregates to form a strong concrete.

- The higher Aggregate/cement ratio means the cement content is less in the ratio which makes leaner concrete. In leaner content, the cement is very less to make paste material which affects the workability.

- The lower aggregate/cement ratio means the cement is high in the ratio which makes the fatty cohesive concrete which can be easy to handle.

Water Cement Ratio

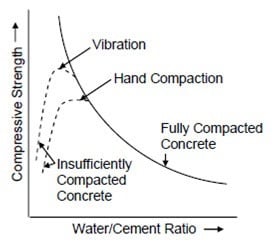

The workability of concrete depends on the amount of water which is mixed with cement to create the proper cement paste.

As per IS code, the recommended water-cement ratio ranges between 0.4 to 0.6 for good workability.

If the water content increases in concrete then the workability also increases but eventually after a certain stage, segregation & bleeding will occur. It develops some serious issues like shrinkage & creep of concrete.

Properties of Aggregates

The aggregate properties affect the workability of concrete as listed below.

- Size – The bigger sizes aggregates has less surface area compared to a smaller size which needs

-

-

-

-

-

-

- Less amount of water to wet

- Less amount of cement paste for lubricating

-

-

-

-

-

-

- Garde – The workability is directly proportional to the grading of aggregates. The well-graded aggregates reduce the voids in between the concrete ingredients.

Types of Cement

The rapid hardening cement will reduce the workability compared to ordinary Portland cement because it is hydrated more rapidly and also its influence on bleeding.

Environmental Condition

The increase in water content should be necessary to increase the workability on hot days. The environment temperature makes the water in the concrete to evaporate soon which affects the workability

So the ambient temperature also affects the workability of concrete.

Type of construction work

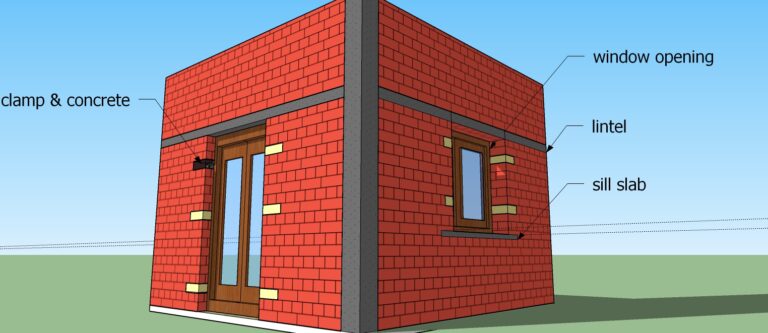

High workability is required for heavy reinforcement formwork because it is not possible to use vibration to compact the concrete. So the concrete has to be compact & settle by itself.

As we know it’s easy to place concrete on slab than a beam.

Use of Admixture

The workability may be affected by the use of admixture. The main purpose of admixture usage on concrete is to increase the workability and less amount of water is enough while using it.

How can we increase the workability of concrete?

Concrete workability can be increased by

- Using the proper water content ratio

- Using the right Grading & size of aggregates

- Proper Mixing of concrete (Hand Mixing)

- Transit the concrete on time

- Usage of Admixture

Workability test of concrete

So far we have discussed the importance of concrete workability & the factors affecting it. Now its time to analyse the concrete that you made according to the instruction

Here we have listed some of the lab and field tests to measure the workability.

- Slump test – The slump test is performed to measure the workability & consistency of concrete at the site but it does not give accuracy but it is useful to detect the uniformity of concrete mix.

- Vee-Bee Test – This test is conducted to measure the consistency of concrete & it is measured in Vee -bee seconds.

- Compaction Factor Test – The compaction factor test is generally not conducted at the field due to the size of the apparatus. The compaction factor test is suitable for low workability concrete.

- Kelly Ball Test – Another test which is commonly used at the field to find out the consistency of concrete. The Kelly ball test gives accurate results in a short period.

- Flow Table Test – The flow table test is performed to find out the workability of concrete and it is conducted in a laboratory.

Read the article at least 2 times to understand the topic better.

Hope you have learnt something useful today. Happy Day 🙂