If you are working in a small to medium size company then you must see this scenario every day.

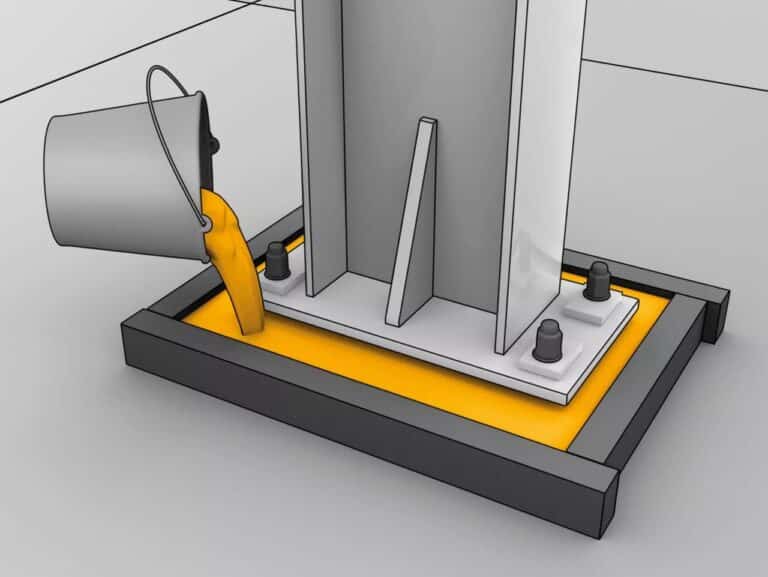

Every contract labour working on concrete placement tries to pour extra water to the concrete. Is that what makes them happy? Absolutely.

Because with the optimum water-cement ratio the concrete mixture or cement mortar will look dense and weigh more to transfer (via cement-pond). So they all try to add water to them which makes the concrete less hardened and the cement pond looks full which is easy to transport.

Is this correct? Absolutely not. Adding too much water affects the quality of the concrete or cement mortar.

In this post, we are going to discuss

- What is the water-cement ratio?

- Role of Water in Concrete

- Effect of water-cement ratio on concrete strength

- Workability of concrete

- How to calculate the water-cement ratio

- Minimum water-cement ratio table

- Water cement ratio formula

- Example Calculation of water quantity for concrete

What is Water Cement Ratio?

The ratio between the water weight to the cement weight is known as the water-cement ratio or W/C Ratio.

Role of Water in Concrete or Cement Mortar

As you all know concrete is a macro content which consists of Cement, Sand and coarse aggregates.

To make a concrete mixture to withstand required compressive strength, Cement needs to react with other micro materials such as sand, coarse aggregate.

Water, when mixed with cement, reacts and forms cement paste (chemical process) which will bind the other micro materials to form a hardened concrete.

Adding water to the concrete beyond this limit will affect the cement paste strength and eventually breaks the concrete strength.

Effect of Water Cement Ratio on Concrete Strength

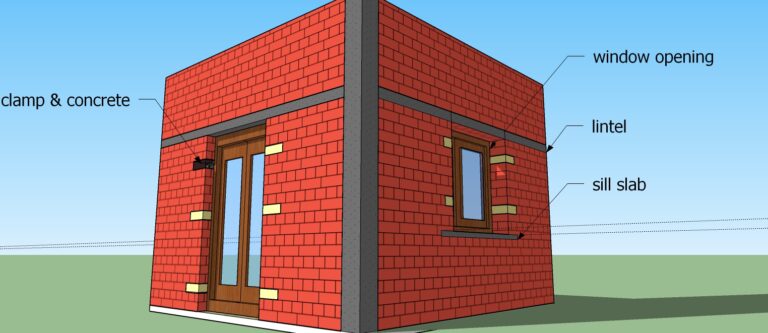

As stated earlier adding too much water will affect the concrete quality. The coarse aggregate and fine aggregates will freely move in the concrete which will be resulted in

- Aggregate segregation – The density of aggregates high compared to water. So the extra water will float above the concrete and make the uneven coarse aggregate segregation.

- Concrete Honeycomb formation – The excess water content will be vaporized after placing the concrete and forms honeycomb formation.

Minimum Water Cement Ratio Table – IS code 10262

Water is the critical element that makes or breaks the concrete quality. To obtain perfect concrete, we need the minimum water-cement ratio

| Exposure | Plain Cement Concrete | Reinforced Cement Concrete | ||||

| IS 10262 | Minimum Cement Content | Water Cement Ratio | Grade | Minimum Cement Content | Water Cement Ratio | Grade |

| Mild | 220 | 0.6 | 300 | 0.55 | M20 | |

| Moderate | 240 | 0.6 | M15 | 300 | 0.5 | M25 |

| Severe | 250 | 0.5 | M20 | 320 | 0.45 | M30 |

| Very Severe | 260 | 0.45 | M20 | 340 | 0.45 | M35 |

| Extreme | 280 | 0.4 | M25 | 360 | 0.4 | M40 |

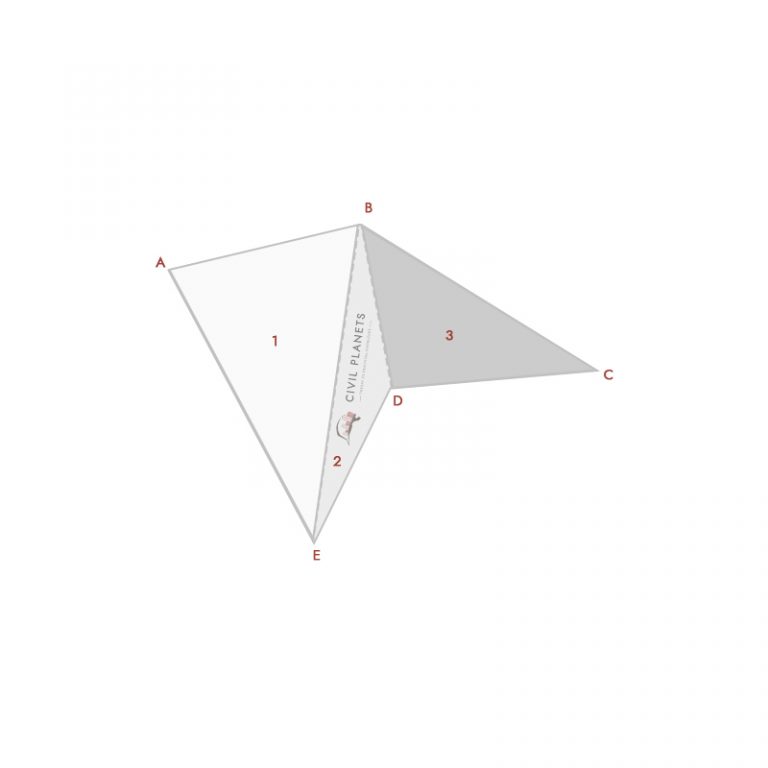

How to Calculate Water Cement Ratio?

|

Example Calculation of water quantity for concrete

This calculation applies only for the nominal mix.

From Example, Calculate Water Cement Ratio for M20 RCC

From the table, we know the water-cement ratio is 0.55 for M20

We take 0.55 as a ratio of W/C. M20 is a volumetric mixing, so we have to take 0.55 of water in volume of cement.

Therefore, the unit weight of cement = 1440 kg/m3.

Quantity of water = 0.55 x 50/1.44 = 19.1 Liters (1 bag cement = 50 Kg)

So the required quantity of water is 19.1 Liters per cement bag.

For Easy calculation Refer Unit weight of materials.

6 Comments

Thanks for useful knowledge…..

Thank you!. Stay in connect

Thanks for the information..

Glad!… you are welcome.

This does not look correct. Looking at some other sites, it seems that the ratio is specified as a volumetric calculation, not by mass. Since the cement has a density of 1.44, the water added should be 0.55 x 50 / 1.44 (because 50kg of cement occupies 50/1.44 litres of volume). I would be interested in your comments.

Hello John, Thanks for the suggestion. You are right. We have updated the same.