Have you seen wet clay soil where the water evaporates quickly and then makes the soil surface look like below?

What is shrinkage in concrete?

Like in the clay soil, concrete also changes in volume after evaporation of water and makes cracks.

The process of volumetric change in concrete due to the evaporation of water content is known as the shrinkage of concrete. The shrinkage cracks start to appear on the surface due to the moisture evaporation without any external load.

How much does a concrete slab shrinkage?

As per the research, usually, the concrete slab can shrink as much as 12.7 mm per 100 feet.

What causes concrete shrinkage?

|

|

|

|

|

A single most important influencing factor is water apart from the below,

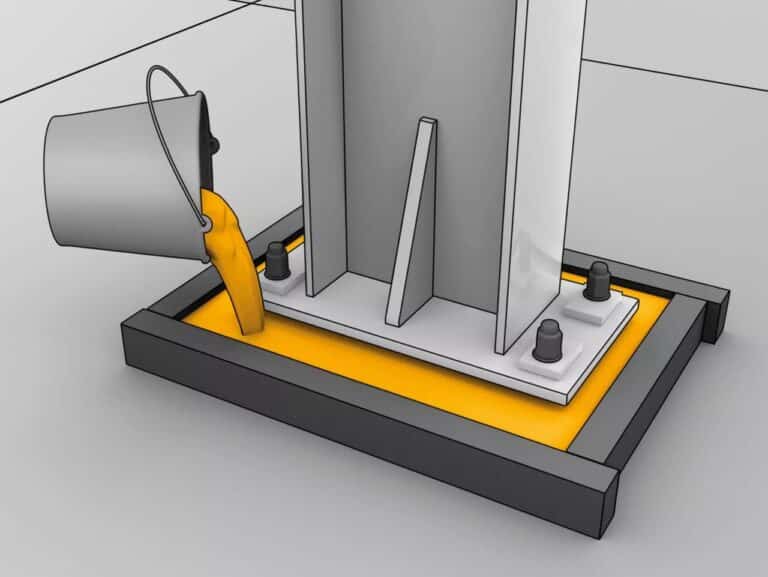

- Environmental Condition – The shrinkage appears more when the concrete is poured in hot climate conditions where the excess heat makes the water molecules to evaporate quickly and makes the concrete to shrink

This is the reason why we insisted on wet the shuttering area by water on-site to cool it.

- Water Cement Ratio – Due to the improper water-cement ratio, the concrete starts to swell the excess water to the surface, which is known as bleeding. More water content mixed concrete increases the shrinks compared to the dry mix concrete.

- Time – As per the detailed research result, the shrinkage process will be happening in concrete for years. 50% of shrinkage occurs in the first two months, and 80% of shrinkage happens in 1 year.

- Small Size Aggregates – The small size of aggregates may increase the porosity of concrete where the fine aggregate can’t enter, but water does. Once the concrete settles, the water evaporates and leads to the shrinkage in concrete.

- Delayed Curing – Since the concrete structure is mostly exposed to hot environmental conditions, which leads to water evaporation, delayed or intermittent curing also leads to shrinkage. We have discussed irregular curing of the crazing of the concrete topic.

- High heat-producing cement – When we use some particular types of cement in concrete, it affects. The Rapid hardening cement & High alumina cement will produce more heat compared to ordinary portland cement. The water evaporation increases when the cement develops more heat, so the concrete shrinkage also increases.

Types of shrinkage

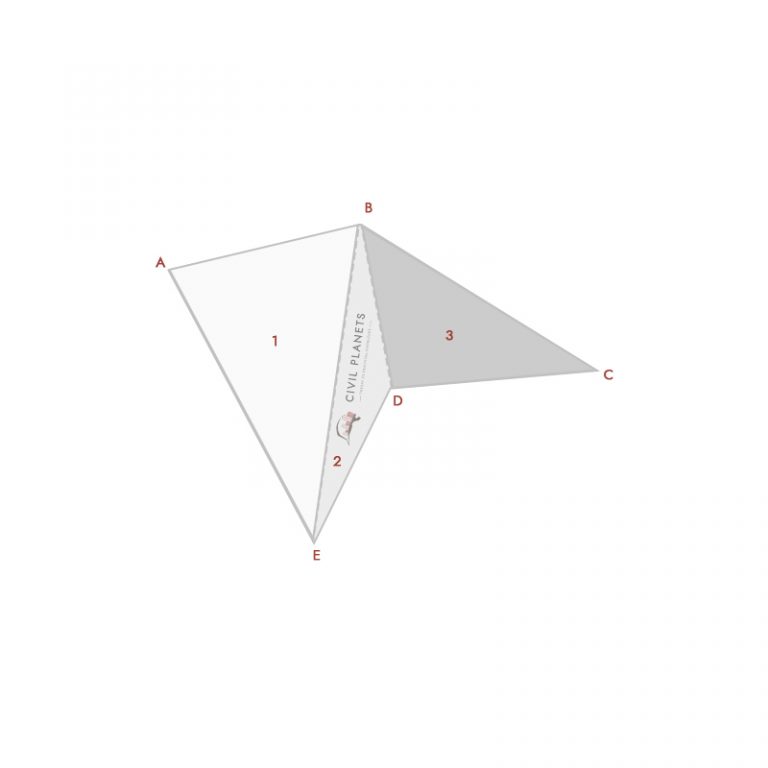

Plastic Shrinkage – The plastic shrinkage will be happening in horizontal surfaces of the concrete after the

Drying Shrinkage – The drying shrinkage is a continual process and happens in hardened cement concrete surfaces due to the evaporation of water molecules at the final setting time of concrete.

Autogenous Shrinkage – The impact of autogenous shrinkage is very minimal because it happened on the concrete surface due to the non-movement of water molecules in concrete. It develops a minor magnitude of shrinkage in concrete.

Thermal Shrinkage – The thermal shrinkage occurs in concrete surfaces due to the high-temperature

Carbonation Shrinkage – Mostly carbonation shrinkage will happen at the mid-level temperature. The carbon dioxide makes chemical reactions with a water content of hydration cement concrete. Then the carbonation penetrates the concrete and develops cracks in the concrete surface.

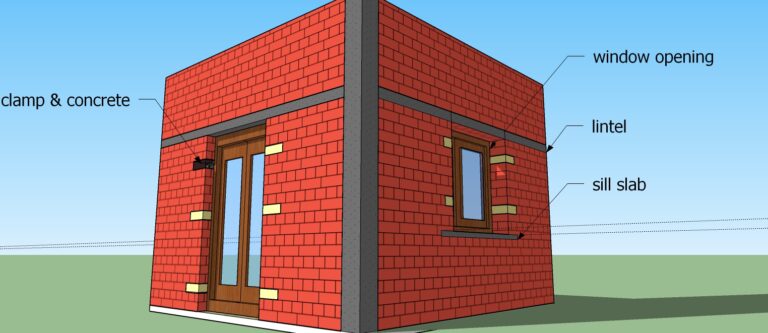

Prevention of shrinkage in concrete

- The concrete should be covered either by a polythene sheet or wet cunny bag to start the curing immediately after the initial setting period.

- Make sure to use proper water-cement ratio along with proper mixing of concrete.

- Avoid rich cement content usage in concrete; it evaporates the water rapidly.

- Use admixture and plasticizer to reduce the quantity of water in concrete.

- Ensure the proper workmanship and avoid bleeding & segregation of the concrete.

- Ensure the material quality. The fine particles of sand-like silt, mica, may produce the shrinkage in concrete.

- The concrete should be poured into relative humidity conditions.

- Mostly the large volume concrete should be poured in the night time; it will help to decrease the shrinkage in the concrete surface.

Hope you enjoyed the article. Happy Learning 🙂