Have you seen random fine cracks on concrete structures that look like crack?

It is called crazing or spider cracking.

What is Crazing of Concrete?

Typically, a continuous hexagonal shape on the concrete surface that looks like a spider web is known as crazing.

It develops in the early stage of fresh concrete and is rarely more than 3 mm deep. These types of cracks are most likely visible after curing the area.

Why does this happen? – Causes

There are numerous sources for this type of cracks to occur

|

|

|

|

|

- Intermittent Curing – Making the concrete dry for some time and curing is known as intermittent curing. The evaporation factor will be more when the concrete is dry. When we dry wet the concrete, the surface tries to absorb the water inside and makes the crazing appear on the surface.

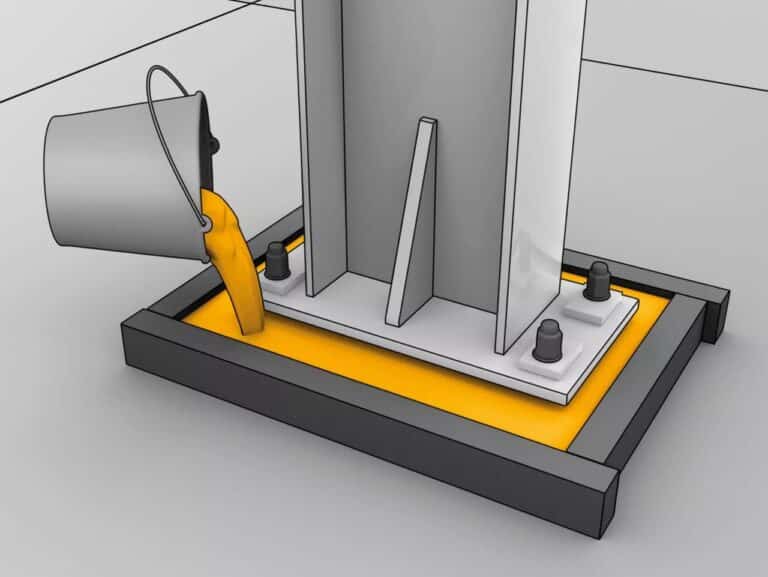

- Excess Water Cement Ratio – Using excessive water leads to crazing. After the concrete has placed, the excess water settles at the top, which moves the cement particle and makes a thin layer on the surface. Later it will be dried and cause crazing on concrete.

- Poor Workmanship – Using more hand trowel actions while placing the concrete leads to the improper settlement of concrete and raises cement paste to the surface and makes water bleeding. It later forms the crazing.

- Excessive Use of Cement – To give a smooth finish on the concrete finish, labours try to sprinkle cement on the surface. Later the cement will dry and make way to crazing.

- Excessive Vibration – Excessive vibration on the concrete makes the blue metal to settle down and let the cement slurry to the top which develop the crazing

- Use of High Workability Concrete – Using high workability concrete for easy placement often contains excess water which makes the cement to settle at top.

Difference between cracking and crazing

Except for Plastic shrinkage cracks all other cracks developed on the hardened concrete surface such as

- Expansion Cracks

- Heaving Cracks

- Settling Cracks

- Overload Cracks

are the result of load stress, which damages the concrete considerably.

Crazing, on the other hand, rarely goes beyond 3 mm deep, which does not affect the concrete strength. It makes the building owners go crazy over us.

Prevention of Crazing

Make all the precautionary measures to avoid the causes that we have discussed above.

- Never allow the labour to disturb the concrete by hand trowels. Make it settle down and finish the concrete surface by the end.

- Start Curing at the early stage. Avoid making the concrete to dry and then wetting. Curing plays a vital role in developing the crazing on concrete.

- Use moderate workability slump concrete.

- Avoid using excessive vibration on the concrete, which results in cement slurry settling on the surface.

- Don’t attempt to sprinkle the cement to remove the water bleed on the surface.

- Make sure to wet the shuttering area before placing the concrete to avoid unnecessary evaporation from the concrete.

Is Concrete Crazing bad?

Unlike plastic shrinkage cracking, these will not affect the concrete durability. However, it is advisable to take precautionary measures to avoid such crazing on concrete.

Hope you have enjoyed the topic. Happy Learning 🙂