What is the compaction factor test?

The test used to find out the compaction factor (external force required) for a low workability concrete is known as the compaction factor test. It is conducted in the laboratory.

The compaction factor is the ratio between partially compacted to fully compacted concrete.

Why we use the compaction factor test?

The test performed as per IS code 1199, and it gives accurate results compared to slump cone tests because low workability concrete may fail by doing slump tests.

Principles of Compaction Factor Test

The compaction factor test is performed to find out the workability of concrete where the coarse aggregate size does not exceed 38mm.

The compaction factor test can be used in both field & lab based on the circumstances.

Apparatus Required

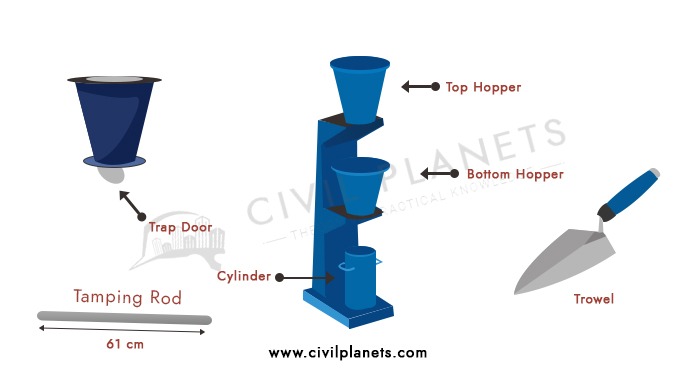

- Compaction Factor Machine

- Trowel

- Hand scoop

- Weighing machines up to 30 Kg

- 16mm dia Tamping Rod with 600mm height

The detailed dimension of the compaction factor testing machine components has been given below.

| SI | Components | Dimension in mm |

| 1 | Upper Hopper A | |

| Top internal diameter | 254 | |

| Bottom internal diameter | 127 | |

| Internal height | 279 | |

| 2 | Lower Hopper B | |

| Top internal diameter | 229 | |

| Bottom internal diameter | 127 | |

| Internal height | 229 | |

| 3 | Cylinder C | |

| Internal diameter | 152 | |

| Internal height | 305 | |

| 4 | Distance between bottom of the upper hopper and top of the lower hopper | 203 |

| 5 | Distance between bottom of lower hopper and top of the cylinder | 203 |

Test Procedure

- First thing, the apparatus should be free from dust & moisture.

- Note down the empty cylinder weight as W1.

- By using a hand scoop, place the freshly mixed concrete on top hopper up to its rim.

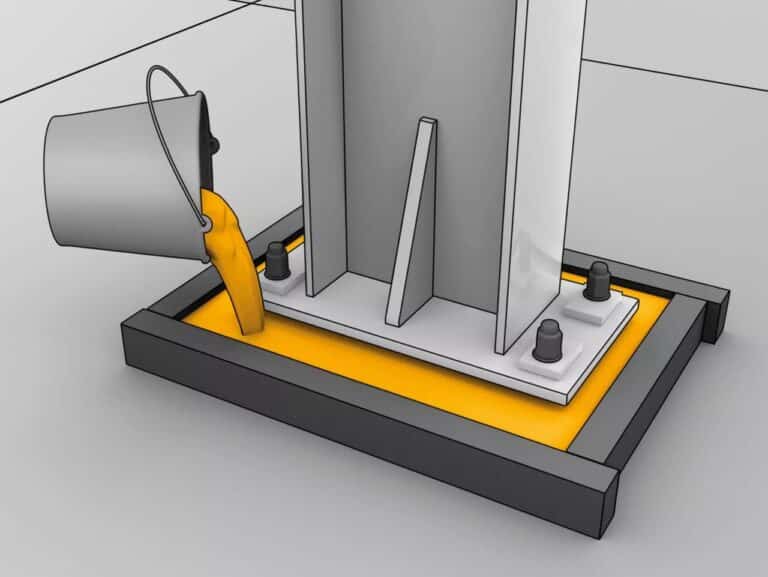

- Then slowly open the trap door of the top hopper, now the concrete falls to the bottom hopper. In case some concrete particles stick on the top hopper, use the tamping rod gently to push the concrete.

- Now open the trap door of the bottom hopper, and the concrete will fall to the cylinder. Then remove the excess concrete from the cylinder and level it by using the trowel.

- Note the concrete cylinder weight as W2.

- Now remove the concrete from the cylinder and again place the same concrete into the cylinder by 3 layers. Each layer should be tamped 25 times by the tamping rod.

- Now weigh the cylinder and note it as W3.

Compaction Factor Lab Test Video

Video Courtesy – MOBILE TUTOR

Compaction Factor Formula

Compaction Factor (CF) = Partially compacted Concrete Weight /Fully compacted Concrete Weight

Partially compacted concrete weight Wp = W2 – W1

Fully compacted Concrete Weight Wf = W3 – W1

Compaction factor CF = Wp/Wf

The compaction factor value should be between the range of 0.7 to 0.95. Recommended compaction factor value is given below for different concrete workability.

| Degree of Workability | Compaction Factor |

| Very Low | 0.78 |

| Low | 0.85 |

| Medium | 0.92 |

| High | 0.95 |

Observations & Test Results

Lab Report

| # | Description | Sample 1 | Sample 2 | Sample 3 |

| 1 | Weight of Empty Cylinder (W1) | |||

| 2 | Weight of Empty Cylinder + Free Fall Concrete(W2) | |||

| 3 | Weight of Empty Cylinder + Hand Compacted Concrete (W3) | |||

| 4 | Weight of Partially Compacted Concrete(WPÂ = W2Â – W1) | |||

| 5 | Weight of Fully Compacted Concrete(WFÂ = W3Â – W1) | |||

| 6 | Compaction Factor = WP/ WF |

Which one is the best test to determine the workability of concrete? Slump test or compacting factor?

If accurate results are required then the compaction factor test is best, else do the workability test by slump cone method because it is easy to do in the field.