The consistency test and soundness test of cement are the main tests used to measure the quality of cement before use in construction activity.

The construction work can’t be easy & firm without the use of cement. In every stage of construction activity, cement occupies a vital role.

Different types of tests are performed on materials to know the quality and strength of the material. The following tests are mainly performed on cement to know its quality and strength.

- Initial and final setting time of cement test

- Consistency cement test

- Compressive strength test

- Soundness test of cement

What is the soundness of cement?

The cement may slightly change its volume after harden state. The cement’s ability to retain its original volume after harden state is called soundness of cement.

In other words, the volume difference of cement before and after the hardened state is known as the soundness of cement.

The soundness test of cement determines

The properties of cement are based on the ingredients which are used for manufacturing the cement. The following are the primary and significant molecules of manufacturing cement.

- Silica

- Iron Oxide

- Calcium sulfate

- Sulfur trioxide

- Alkaline

- Lime

- Alumina

- Magnesia

Each ingredient will have different properties which contribute to the formation of perfect cement. However if any of the above exceeds their allowable ability it reduces the durability and affects the performance of the structure.

For example, The lime is the major constituent that makes the cement set in a particular period. More lime content will affect cement property, which may induce cracks and reduce the durability of concrete or plaster.

So the soundness test is performed to determine the excessive presence of lime content in cement.

IS code for soundness of cement

The soundness test of cement shall be conducted as per IS 4031 Part 6 and the Le chatelier apparatus confirming as per IS code 5514.

Le-chatleir’s Soundness Test

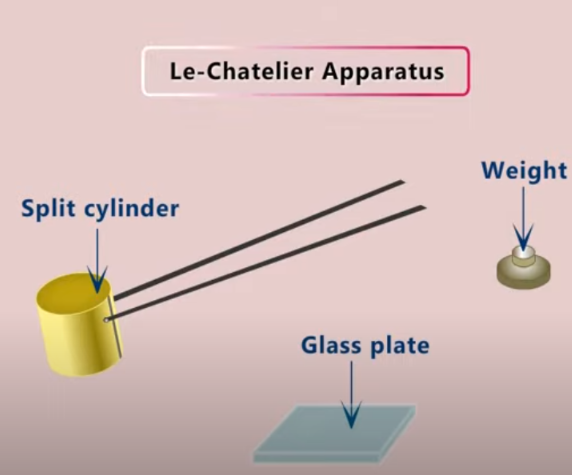

Required Apparatus

- Le-chatelier mould

- Weighing Balance

- Distance Measuring scale

- Glass Plate – 2 Nos

- Water bath

- Pan

- Trowel

- Oil

Procedure

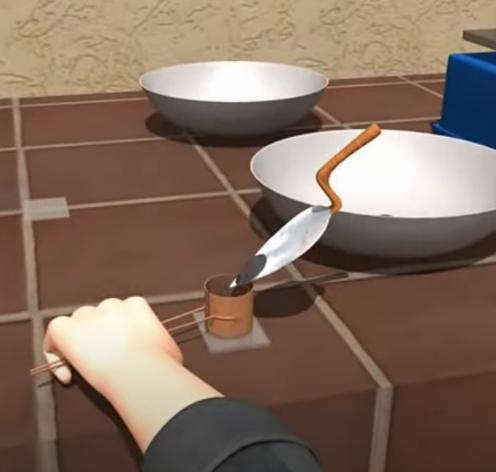

- First, apply the oil on the surface of the glass plate and the Le-chatelier mould.

- Now measure and take 200grams of cement and add 0.78 times water to ensure standard cement consistency.

- Then mix the cement well with the trowel to get the excellent consistency of cement paste.

- Now fill the cement paste into the mould, cover the mould with the glass plate, and place a small weight piece over the glass plate to ensure non-movement of the glass plate. Hold the mould handle gently while filling the cement.

|

|

- Now submerge the whole mould set into the water at room temperature for 24 hours.

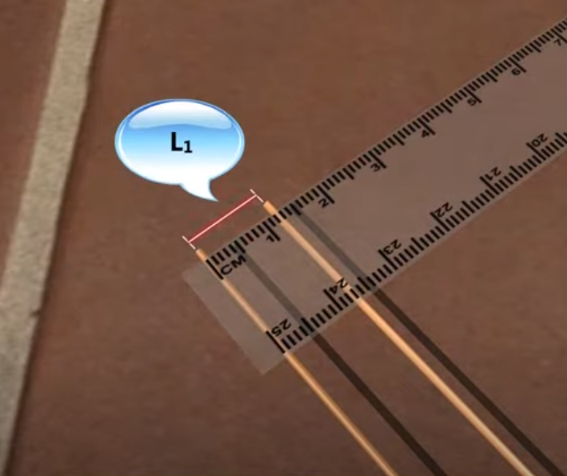

- After removing the mould from the water, measure the distance between two indicators near the value of 0.5mm, and note down as L1.

- Now again submerge the mould into the water up to the water boiling point for 3 hours, allowing it to cool at room temperature.

- Measure the distance of indicators and note it down as L2.

Calculation

Soundness or expansion of cement = L1 – L2

L1 – Measurement is taken at room temperature of mould immersion

L2 – Measurement is taken at water boiling temperature of mould immersion

Conclusion

The allowable limit of expansion should not be greater than 10mm for OPC cement, PPC, Rapid hardening cement, low heat cement, and super sulphated cement.

Test Precaution

- The measured value should be near 0.5mm.

- Ensure the water was not passed into the mould while at immersion.

- Don’t apply more pressure while filling the cement into the mould.

Happy Learning 🙂