The bitumen is a by-product material of petroleum. It is mainly used in construction activities.

It is used primarily in highway construction. Throughout the lifetime of the road, it exposes to hot climatic conditions and heavy traffic load. To ensure quality and strength, bitumen is subjected to various tests.

The following tests are conducted to determine the properties of bitumen.

- Flash and Fire point test

- Stripping value test

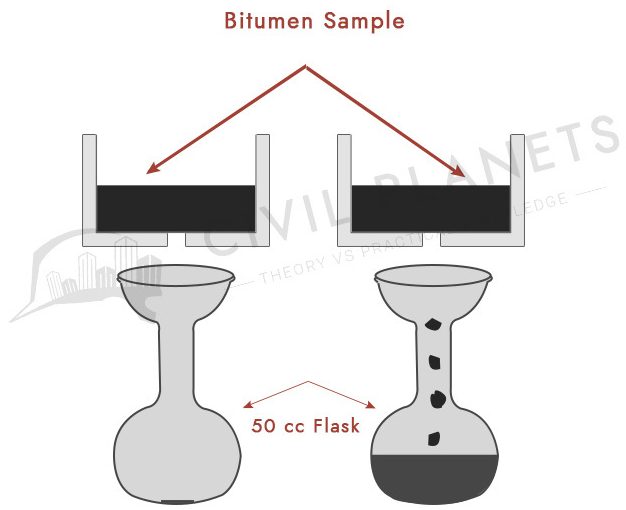

- Bitumen extraction test

- Ductility test

- Float test

- Penetration test

- Loss on heating test

- Softening point test

- Specific gravity test

- Viscosity test

- Water content test

Flash and Point Test

The flash and fire point test has been conducted to determine the safe temperature work of bitumen. Sometimes the bitumen will be flammable in natural atmospheric conditions.

The lowest temperature of bitumen that induces the material to vapour and momentarily catch fire in the form of flash is known as a flashpoint. The lowest temperature of bitumen that causes the material to ignite and burn at least for 5 seconds is known as fire point.

The flash and fire point test shall be conducted as per IS code 1209.

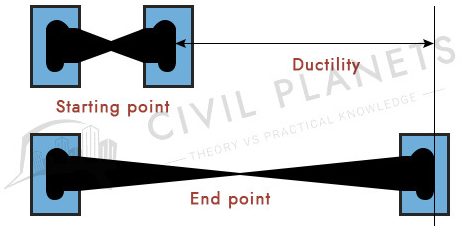

Ductility Test

The ductility test has been performed to determine the elongation length of bitumen at a specific temperature. It is conducted as per IS code 1208

The bitumen elongation will be measured in cm or mm, and the ductility test is performed at 27°C at the rate of pulling 50mm per minute.

Float Test

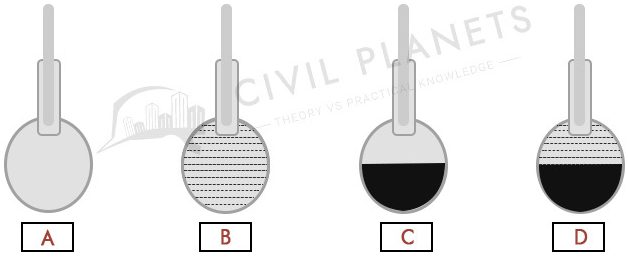

The float test of bitumen has been conducted as per IS code 1210 to find the consistency of the bitumen.

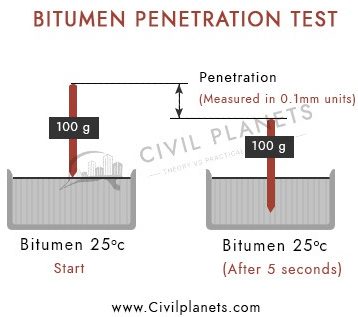

Penetration Test

You may be aware of the grade of cement, which is classified based on the value of compressive strength.

The bitumen also graded based on its penetration value. Usually, the bitumen will be graded as VG – 80/100, VG – 60/70, VG – 30/40.

The grade 80/100 represents the penetration value of bitumen, which lies between 80 to 100, which arrives from the penetration test. The test is conducted as per IS code 1203.

Bitumen penetrated in a semi-solid state at the temperature of 25°C by a steel needle carrying 100gm load for 5 seconds to measure the consistency & hardness of the bitumen is known as a penetration test of bitumen.

Lower penetration value bitumen is used for hot climate road construction and higher penetration value bitumen used in cold climate road construction.

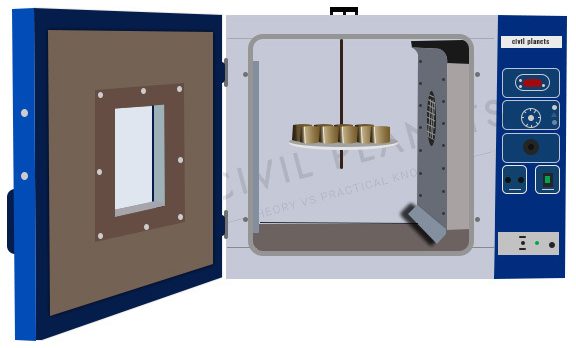

Loss on heating Test

The loss of heat test is conducted to find the bitumen weight loss during the heat. The presence of water molecules in the bitumen evaporates while heating and the mass of bitumen will be reduced.

So to know the mass looseness of bitumen, this test is performed as per IS code 1212.

Weight of bitumen sample weighed as W1. It will be heated at 163°C in the oven for up to 5 hours.

Now the bitumen sample again weighed as W2. The ratio between W1 & W2 is called weight looseness of bitumen.

The weight loss of the bitumen percentage should not be greater than 2%.

Softening Point Test

The softening point test is performed to determine the melting point of bitumen at a certain degree of temperature.

The other name of the softening point test is a ring & ball test. The bitumen will not be suited if it is melting at natural atmosphere temperature and leads to vehicle skid.

So the softening point test is conducted to ensure that the bitumen can withstand hot conditions.

The softening point test is conducted as per IS code 1205.

Specific Gravity Test

The specific gravity of bitumen is in the range of 0.9 to 1.5. Determination of specific gravity for bitumen is advantageous to classify the bitumen while mixing with the aggregates on a volume basis.

It is determined by comparing the bitumen weight with water weight equal to the weight of bitumen.

The specific gravity is determined by the pyknometer method as per IS code 1202.

Viscosity Test

The viscosity test is performed to find the fluidity of bitumen. The ability of bitumen spreading over the pavement area is known as the fluidity of bitumen. The lower viscosity of bitumen mixed with aggregate makes it as smooth.

The bitumen viscosity is determined by viscometer as per IS code 1206. The bitumen viscosity value is measured by the time taken for 50 ml bitumen passing to the orifice cup.

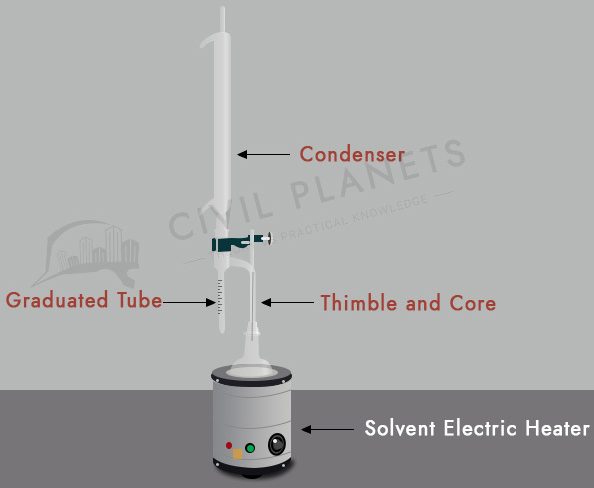

Water Content Test

Foaming occurs on bitumen when the bitumen is heated beyond the water boiling point. The dean and stark method is used to find the presence of water content in bitumen as per IS code 1211.

The bitumen sample will be heated over the water boiling point and the evaporated water molecules collected and measured. The quantity of water present in a bitumen expressed as a percentage by mass of the bitumen.

The percentage of water content should not exceed 0.2% of bitumen weight.

Happy Learning 🙂