The water seepage on the roof will induce corrosion in concrete, and after a certain period, the entire structure will start to deteriorate.

We do not need to explain the effects of water leakage on a structure. Just pointed out a few things.

Effects of water leakage

- Cracks may form on the concrete surface.

- The leakage water reacts with the steel reinforcement and corrodes the concrete.

- The household things and wooden material may cause fungus due to the presence of water inside the buildings.

- High maintenance costs required.

Waterproofing is the only solution to avoid water leakages in the buildings. The brickbat Coba, lime mortar mix has been widely used as waterproofing treatment to prevent water penetration on the slab.

What is brick bat coba? And Why do buildings need it?

Nowadays most of the building roofs are constructed by a reinforced concrete slab, but there is a possibility of water leakage inside the building which leads cracks in the future.

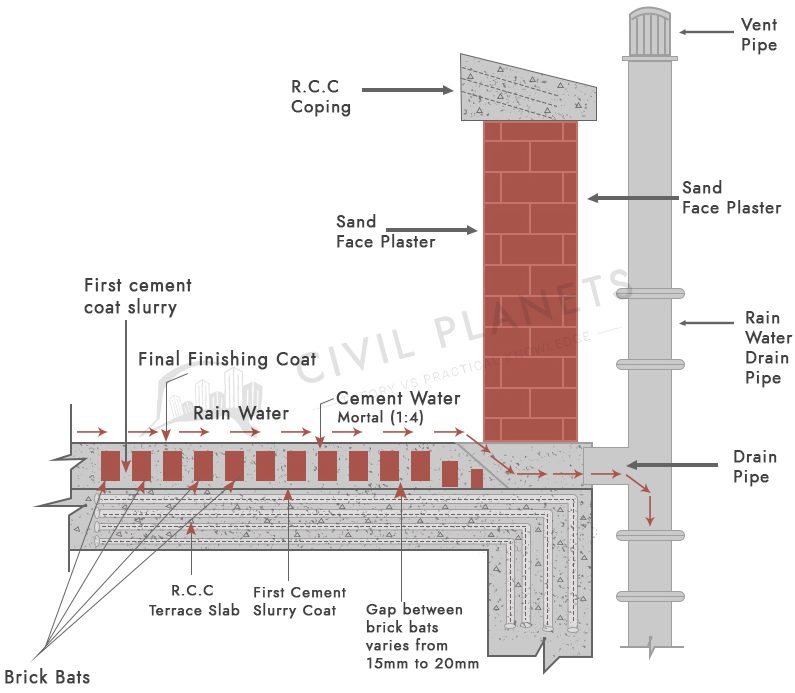

The brick bat Coba materials are laid on the flat roof surface at the thickness of 75mm to 150mm with the cement mortar mix of waterproofing chemicals at the proper slope to drain out the water in the rainy season. Also, to prevent water penetration.

The brickbat Coba waterproofing treatment gives the comfort of thermal insulation inside the buildings.

Step by Step Procedure of Brickbat Coba Waterproofing

- The RCC roof surface should be clean and should not have any major undulations.

- The roof surface must be scrubbed by wire brush and cleaned.

- If any cracks found on the surface must be rectified immediately.

- Now apply the concentrated cement slurry on the roof surface and the parapet wall upto 300mm height at 2.5kg to 2.75 kg per sqm.

- After that, the 1:4 cement mortar mix (rough mortar) will be applied on top of the cement slurry at 25mm thickness.

- Now brickbats will be laid either 75mm or 150mm thick with 10 to 15mm gaps for filling the mortar. The brickbats must be soaked well before placing on the surface.

- After putting the brickbat, it should be cured for 24 hours

- After that, the gaps should be filled with the cement mortar at the ratio of 1:4.

- Now the waterproofing chemical compound is mixed with the cement mortar, which is not more than 3% to 5% per cement bag. Apply the mix at 20mm thickness as a final layer over the brickbat.

- The parapet wall also should be plastered by the cement mortar in 20mm thickness with a smooth finish.

- Finally the brickbat waterproof should be cured at a minimum of 7 to 10 days by any type of curing method.

Advantages of Brickbat Coba

- It is an economical waterproofing method.

- The brickbat waterproofing treatment will be complete in a short period.

- High skilled manpower not required.

- Masonry brick wastages can be utilized for the waterproofing.

Disadvantages of Brickbat Coba

- The main disadvantage of brickbat Coba is the dead load. It increases the dead weight of the structure when using bricks.

- Immediate rectification required if any cracks have been found on the roof surface else, it may cause trouble in the future which may not be solved quickly.

Happy Learning 🙂