Have you ever wondered why there are two types of bars used in slab reinforcement, namely Main bar and distribution bar?

We have discussed the difference between one way slab and two way slab. Also know the load handling of each slab type.

There is where the underlying answer is, why we use two different sizes of bars in the slab reinforcement.

Typical Scenario Example

Take a wooden writing pad and support them only at two ends. Now apply force on the top middle of the pad. You can observe the deflection below the pad. The pad bends at the centre and rises at the support.

What you’ve seen is the typical slab load handling scenario.

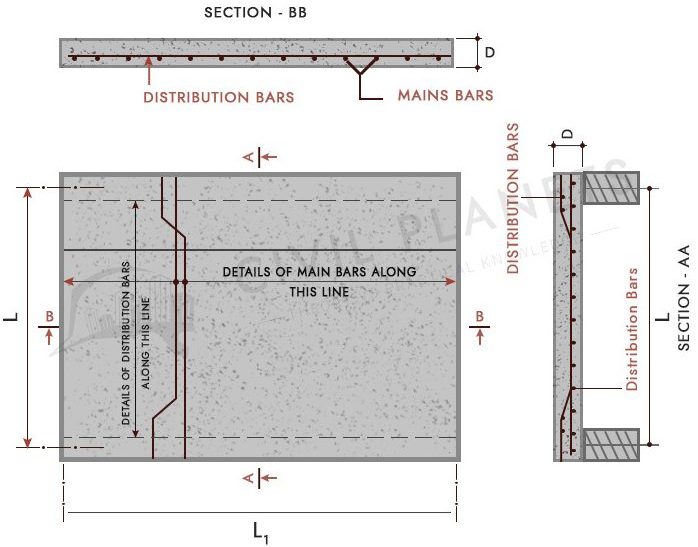

Main Bars

If you observe carefully, you can see that the pad tends to bend (deflection) along the shorter span. It creates bending stress in the middle of the slab and support end.

So to resist the bending moment developed in the shorter span at the middle bottom & top of the support, the main bars (cranked bars) of larger size are provided at the bottom of the slab.

Distribution Bars

Distribution bars, on the other hand, do not transfer any bending loads to the support. It is only provided there to resist the shear stress and slab cracks that are resulted by the main bar load distribution.

That means when the main bar bends at the bottom, it makes the concrete crack at the bottom of the slab.

Difference Between Main Bar and Distribution Bar

| Main Bar | Distribution Bar |

| Provided at the bottom of the slab | Provided at the top of the slab |

| Provided to resist the bending stress | Provided to resist the shear stress and cracks |

| Placed at a shorter span | Placed at a longer span |

| Size of the bar is higher than the distribution bar | Size of the bar is less than the main bar |

Happy Learning 🙂