The aggregates used in different construction works such as roads, buildings, pavement etc.

So many different kinds of tests are applied on coarse aggregates such as the impact values test, crushing value test, specific gravity test, and sieve analysis test to know its strength.

What is an abrasion test?

The abrasion test is conducted on the aggregates to know its toughness and resistance such as crushing, degradation and disintegration. It is more like a Charpy impact test for metal toughness.

It is conducted in three different methods.

- Deval abrasion method

- Los Angeles abrasion method

- Dorry Abrasion method

Here we are going to discuss the Los Angeles abrasion test method, which is widely used to determine the abrasion resistance of the coarse aggregates.

Abrasion is nothing but grinding motion of materials against each other.

Purpose of Los Angeles Abrasion Test

Road pavement aggregates are subjected to Los Angeles abrasion tests. Since the road is subjected to continuous motion pressure by vehicles, it may disintegrate the aggregates into small particles due to the heavy abrasion on the road surface.

The aggregate particles of the road surface become dust due to the abrasion, and it disturbs the vehicle driving. Moreover, it may lead to accidents. So it should sustain against motion pressure and should not disintegrate.

How do you calculate abrasion value?

A certain weight of steel ball and the coarse aggregate specimen will be mixed and placed in a drum. Then it would be rotated for a certain number of revolutions.

The percentage of wear loss of aggregate specimens rubbed by the abrasive steel balls is known as abrasion value. The Los Angeles abrasion test method and apparatus specification have been mentioned in IS code 2386 Part 4.

Apparatus required

- Weighing Balance up to measuring 10 Kg.

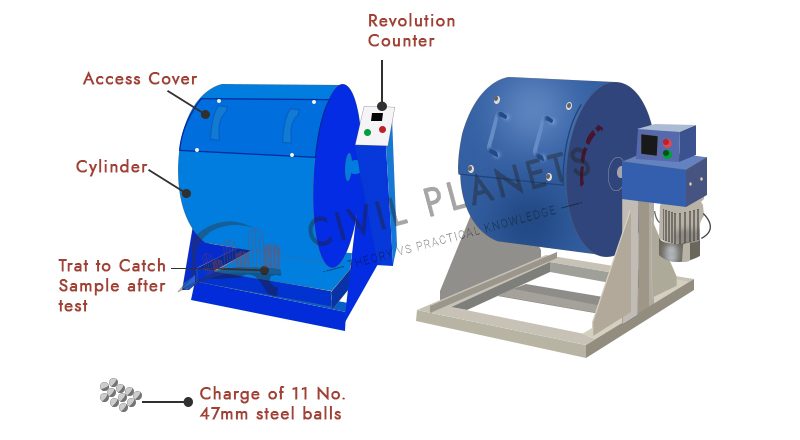

- Los Angeles Test machine – It consists of a closed hollow steel drum with the inner diameter of 700mm and 500mm length which is mounted on a stub shaft.

- Steel ball – Dia of steel ball is 48mm, and the weight will be 390g to 445g.

- IS sieve – 80, 63, 50, 40, 25, 20, 12.5, 10, 6.3, 4.75 and 1.7 mm (as per gradation of aggregate)

- Tray

- Oven

Gradation of aggregate

Different sizes of aggregates are used for different road construction works. Based on grain size, the sample weight will be taken as a specimen for the test.

| Sieve size | Test Sample Aggregate Weight in gm | |||||||

| Passing (mm) | Retained on (mm) | A | B | C | D | E | F | G |

| 80 | 63 | 2500* | ||||||

| 63 | 50 | 2500* | ||||||

| 50 | 40 | 5000* | 5000 | |||||

| 40 | 25 | 1250 | 5000 | 5000* | ||||

| 25 | 20 | 1250 | 5000* | |||||

| 20 | 12.5 | 1250 | 2500 | |||||

| 12.5 | 10 | 1250 | 2500 | |||||

| 10 | 6.3 | 2500 | ||||||

| 6.3 | 4.75 | 2500 | ||||||

| 4.75 | 2.36 | 5000 | ||||||

The number of abrasive steel balls chosen for the test is related to the gradation of the aggregate mentioned in the below table.

| Grading of Aggregates | No of Steel balls | Weight of Steel ball in gm. |

| A | 12 | 5000 ± 25 |

| B | 11 | 4584 ±25 |

| C | 8 | 3330 ± 20 |

| D | 6 | 2500 ± 15 |

| E | 12 | 5000 ± 25 |

| F | 12 | 5000 ± 25 |

| G | 12 | 5000 ± 25 |

Test Procedure

- Choose any grade of aggregate as per the above table. Take 5kg of sample aggregates for grade A, B, C, D and take 10Kg of sample aggregate for grade E, F, G.

- The sample aggregate must be clean from dust particles and should be dried through the oven at 105°C to 110°C.

- Now choose the right abrasive steel ball as per the table mentioned above.

- Note the weight of the dried aggregate sample as W1. Now place both aggregate and steel balls into the drum and lock it.

- Now rotate the drum gently at the speed of 30 to 33 circulation per minute. The number rotation is 500 for grade A, B, C, D aggregates and 1000 for aggregate grade E, F, G.

- After completion of circulation, collect the aggregate sample and place it on a tray.

- Then the collected aggregate sample should be sieved through 1.70mm IS sieve.

- Now weigh the aggregate which retained through the IS 1.70mm as W2.

Abrasion Value Calculation

Abrasion Value = (W1-W2/W1) x 100

W1 – Weight of Dried Aggregate Sample

W2 – Weight of aggregate sieved through the IS 1.70mm.

Minimum two samples have to be tested from the same batch and average the value as the Abrasion value of the aggregate.

Lab Report

| Grade of Aggregate | Description | Sample 1 | Sample2 |

| Weight of Dried Aggregate Sample w1 | |||

| Weight of aggregate sieved through the IS 1.70mm W2 | |||

| Percentage Wear (W1-W2/W1) x 100 |

The limitation of abrasion value for different aggregate has been mentioned in below table as per the recommendation of Indian Roads Congress.

| # | Type of Pavement | Max. permissible abrasion value of aggregates in % |

| 1 | Water bound macadam, sub-base course | 60 |

| 2 | WBM base course with the bituminous surfacing | 50 |

| 3 | Bituminous bound macadam | 50 |

| 4 | WBM surfacing course | 40 |

| 5 | Bituminous penetration macadam | 40 |

| 6 | Bituminous surface dressing, cement concrete surface course | 35 |

| 7 | Bituminous concrete surface course | 30 |

Happy Learning 🙂