A structure has been designed based on the compression strength of concrete. So mostly, the tensile strength of concrete tests are not required to perform at the site. The framed structure built up by the combination of brittle and ductile material.

- Brittle Material – Concrete

- Ductile Material – Reinforcement

The concrete is good in compression force and weak in tension force. So the reinforcement has been provided in concrete to prevent the crack formation.

What is a Tensile strength of concrete?

The concrete’s ability to withstand pull force (Tensile Stress) without breaking is called the Tensile Strength of concrete. The tensile strength of concrete is measured by the units of Force per Cross-Sectional Area (N/Sqmm or Mpa).

Why is concrete weak in Tension?

As above said, the concrete is weak in tension force because of its brittle nature.

The concrete is formed by the mixture of different material cement, fine & coarse aggregates. Each material contains different properties, which results in the properties of concrete as a whole.

During the period of concrete casting, the water-cement ratio gradient makes around the aggregate particles, and the cement paste forms a different microstructure around the concrete. This zone is called the Interface Transits Zone.

Interface Transits Zone

The ITZ is the weakest zone of concrete because the bond between the cement paste and aggregates may be reduced due to concrete bleeding. In compressive stress, the load transferred from one aggregate to another aggregate, and that was not required for unprecedented strength.

At the same time, in tension force, the aggregate pulls away from each other, and it can be easily broken from its shape.

Tensile Strength of Concrete Test

The tensile strength of concrete is an important property when it is to be used in making prestressed concrete structure, roads, and runways, this test shall follow as per the IS Code 5816.

The tensile strength of concrete is generally in the range of 10 % to 12% of its compressive strength.

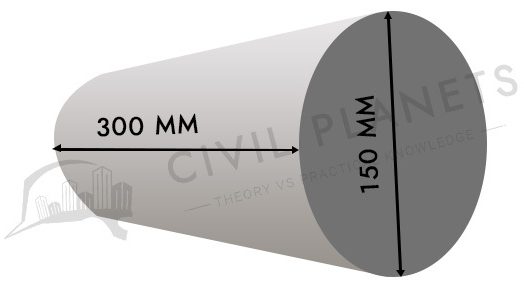

The concrete cube was used to find the compressive strength of concrete, but to find the tensile strength of concrete a cylindrical specimen has to be used.

Split Tensile Strength Test

The direct tensile strength of concrete is difficult to measure. So we use split tensile strength tests.

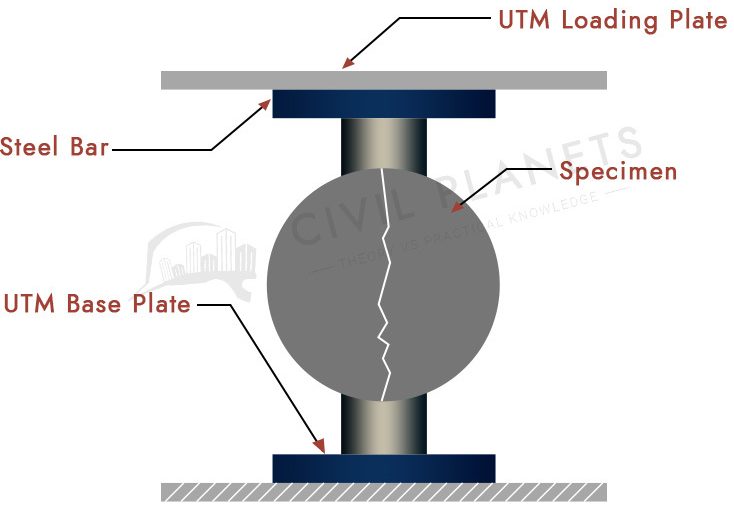

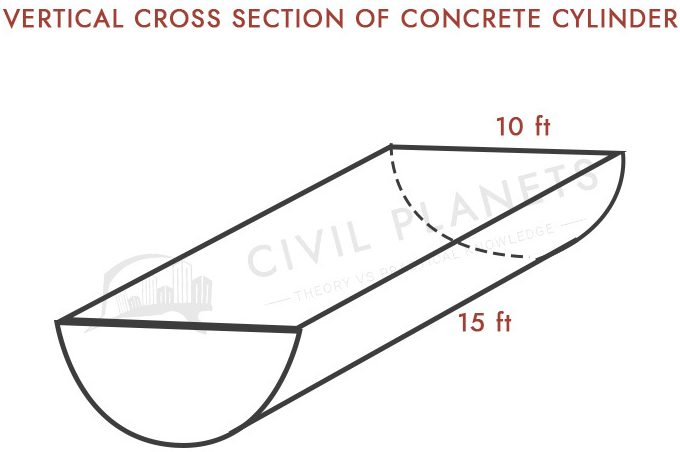

An indirect method to determine the tensile strength of concrete using a concrete cylinder that splits across the vertical cross-section is known as split tensile strength.

Why?

Because in the direct tensile strength tests, it is impossible to apply axial load in the cube, there will always be some eccentricity. The stress applied to the concrete also tends to break it at ends. But we don’t use concrete alone; we use it with reinforcement where the load acts at the centre, not at the ends.

Test Specification

- Specimen – The concrete sample should have a cylindrical shape with a diameter of 150 mm and length 300mm.

- Range of Load – The testing machine can consistently apply the loads in the range of 1.2 MPa/min to 2.4 Mpa/min.

- Age of Test – The test shall be made at the period of 7 days and 28 days. Tests at any other age at which the tensile strength is desired may be made if so required.

- Number of Specimens – At least three specimens should be tested for each period of the test.

Apparatus Required

- Testing Machine (1.2 Mpa/min to 2.4 Mpa/min)

- Tamping Rod (Dia – 16mm, and Length – 600mm)

- Concrete Mould (Made by Steel)

- Trowel

Procedure

- Estimate the adequate ingredients to prepare the concrete with a proper water-cement ratio.

- Ensure that the cube mould should be free from dust and rust.

- Now, pour the concrete into the mould by proper compaction with the help of a tamping rod.

- Finish the top surface as smooth by the trowel.

Curing

- The mould should be covered with a wet gunny bag and placed undisturbed for 24 hours at a temperature of 27 ° Celsius ± 2.

- After 24 hours, the cube specimen shall be removed from the mould, and it should be immersed into the water for 7 or 28 days based on the test.

- The concrete sample shall be taken from the water 24 hours prior to the test, and it should be in dry condition.

Test

- The bearing surfaces of the machine and the loading strip should be free from dust.

- The specimen should be weighed in Newton before the test.

- Now, place the sample centrally between the loading strips and ensure the upper plate is parallel to the bottom plate.

- Then apply the load gradually until the specimen breaks and note down the value.

- The same method has been executed for the other specimens.

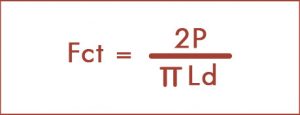

Tensile Strength of Concrete Formula

The below formula calculates the tensile strength of concrete

Fct – Tensile Strength of Concrete

P – Maximum load in N/Sqmm

L – Length of the Specimen

D – Diameter of the specimen

Report

The split tensile strength test gives 5-10% higher value than the direct tensile strength test.

The testing report should have the following

- Age of the Test

- Date of specimen cast

- The weight of the specimen

- The grade of the concrete

- Tensile Strength

| Date | Grade | Age of Test | Specimen | Weight in Newtons | Load (kN) | Tensile Strength Kg/Sq.cm | Average Strength |

| DD/MM/YY | 28 Days | Sample 1 | |||||

| M25 | 28 Days | Sample 2 | |||||

| 28 Days | Sample 3 |

Happy Learning 🙂

2 Comments

Should the specimen be cylindrical. Seems to be the same CTM used for this.

No!.. universal testing machine has to be use for Tensile Test