Many innovations are evolving in the construction industry to enhance the strength and durability of the structure.

Concrete, A major construction material that is strong in compression and weak in tensile load. So the steel reinforcement has been embedded to stabilize the concrete against the tensile force.

Though the reinforced cement concrete is strong in both, there is a possibility of crack occurrence on the concrete surface by anyone of the following reasons.

- Shrinkage crack

- Improper compaction of concrete

- Improper quality of material

- Honeycomb in concrete

- Corrosion in concrete

- Water cement ratio

- Improper workmanship

Different types of special concrete are used for works such as coastal protection structures, power plants, etc.. However, the self-healing concrete (SHC) is a unique innovation.

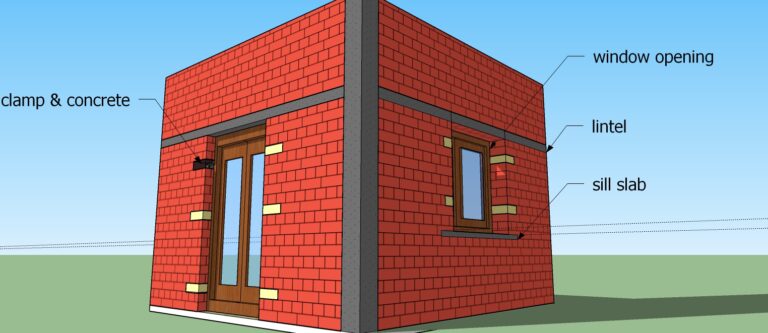

Cracks may occur on the concrete surface after completion of the structure. The moisture content seeps into the concrete surface through a small crack and corrodes the steel and will lead to a collapse of the entire structure.

The SHC gives solutions for the crack rectification in a natural way.

What is self healing concrete?

Usually, the cracks which appear on the concrete surface will be repaired by either applying cement paste, or by penetrating cement grout or epoxy grout.

The cracks on the concrete surface that heal themselves with the help of environmental moisture and air by producing a lime layer is called self-healing concrete.

We know that the cement contains lime particles. Generally, 20 to 30% of cement will not hydrate in concrete. That non-hydrated cement will hydrate when cracks formed on the concrete surface.

The lime particles present in cement now react with the environmental moisture and fill up the fine cracks. The cracks may fill automatically when the width of the crack ranges between 0.05mm to 0.1mm. When the width of the cracks goes beyond 0.1mm, then other types of repair method is required.

Bacterias are used in the self-healing of cracks that happen on concrete surfaces.

Bacterial Concrete

As above said, the self-healing concrete develops lime particles when the cement reacts with the natural moisture to heal the crack.

A special bacteria from the bacillus family, calcium, nitrogen, and phosphorus are mixed with the concrete ingredients to make the bacterial concrete.

Those bacterias can live inactive in concrete over 200 years in dry conditions and the bacterias act as a healing agent.

Types of Bacteria Used in Concrete

The self-healing bacterias are selected from a particular family.

- Bacillus pasteurizing

- Bacillus sphaericus

- Escherichia coli

- Bacillus subtilis

- Bacillus cohnii

- Bacillus halodurans

- Bacillus pseudofirmus

How does self-healing concrete work?

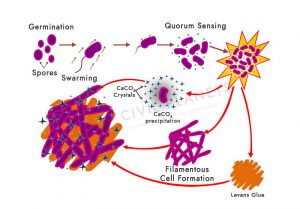

The bacillus bacteria and calcium lactate will be mixed with the concrete ingredients. The bacteria spores grow and consume the oxygen to feed the calcium lactate.

When water seeps into the crack and reacts with bacteria, the calcium lactate produces the lime which will transform as a hardened limestone layer to heal the crack.

Preparation of Bacterial Concrete

The following two methods are used for bacterial concrete.

- Direct mix with the concrete

- Encapsulation in Lightweight concrete

Direct mix with the concrete

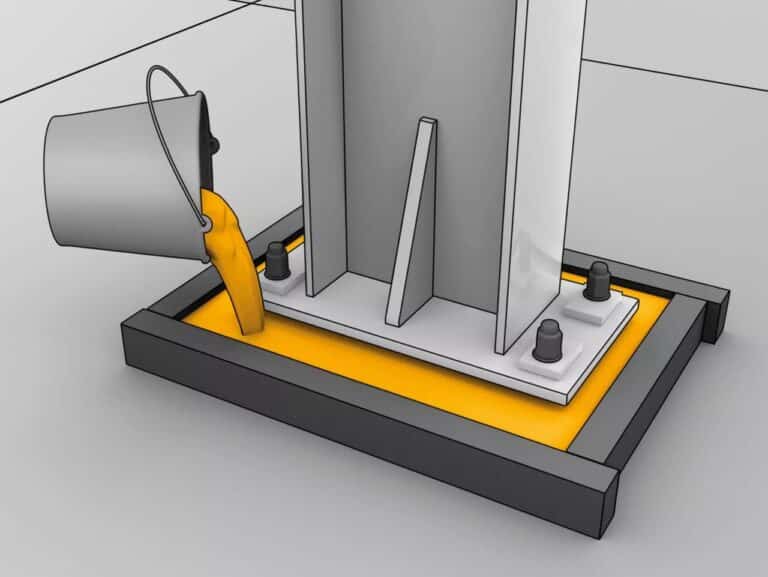

In this method, the specific bacteria spores and calcium lactate directly mixed with the other concrete ingredients. It will not affect the concrete properties.

When the water molecules seep through cracks, then the bacteria react with the oxygen and form the limestone layer to heal the crack.

Encapsulation in Lightweight concrete

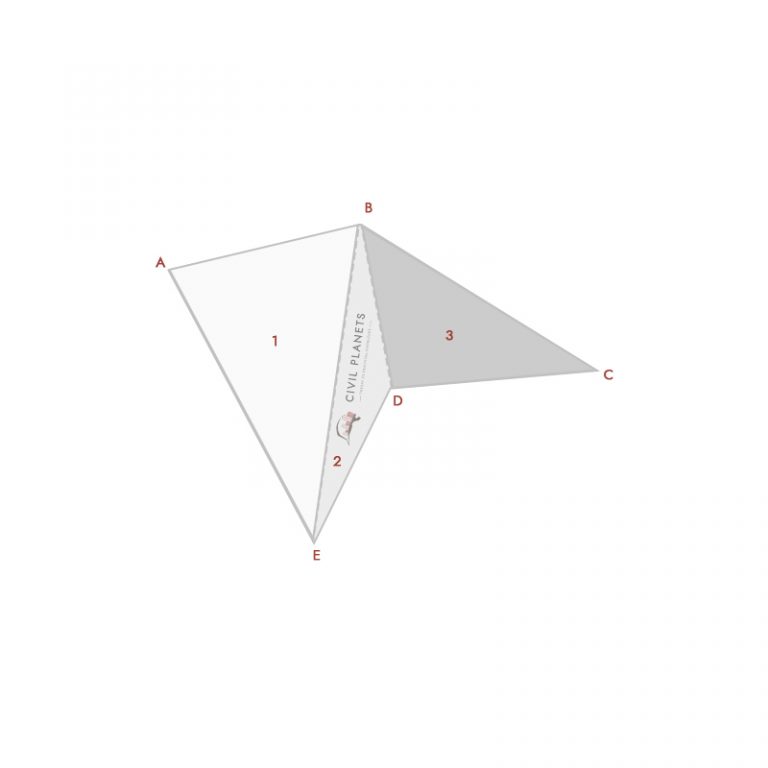

This method is expensive compared to the direct mix method. The bacteria and the calcium lactate inserted in clay pellets. The clay pellets are mixed with the concrete in the ranges between 5% to 8%.

When the cracks appear on the concrete surface, the clay pellets will burst, and the bacteria spores eat the calcium lactate and produce the hardened limestone to seal the crack.

Chemical Process

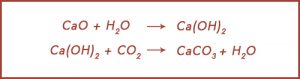

As discussed earlier, generally 20% to 30% of cement in concrete would not be hydrated. So when water comes into contact with the crack, the unhydrated calcium reacts with the water and produces calcium hydroxide. Here the bacteria act as a catalyst to induce the chemical reaction.

The calcium hydroxide reacts with the environmental carbon dioxide and forms the limestone to seal the crack.

The structure may stand beyond its life span by using bacterial concrete. The cement will emit 7% to 9% of carbon dioxide during the production. By using self-healing concrete, the usage of cement and concrete will be reduced, and it is beneficial to reduce environmental pollution.

The compressive strength and tensile strength of the self-healing concrete is 10% to 20% higher than the standard concrete.

Advantages of Self-healing concrete

- The steel reinforcement is corroded mainly by the oxygen. The bacteria spores consume oxygen and prevent it from corrosion. So the life of the reinforcement will be increased.

- The maintenance cost of the structure is very less.

- The erosion of steel reinforcement will be prevented.

- The life span of the structure will improve.

- The concrete becomes impermeable.

Disadvantages of Self-healing concrete

- It is costly.

- At present, there are no IS code norms for self-healing concrete.

- The clay pellets may reduce the compressive strength of the self-healing concrete not recommended for the high rise buildings.

Happy Learning 🙂